Page 163 - Centrifugal Pumps Design and Application

P. 163

Pipeline, Waterflood and CO 2 Pumps 141

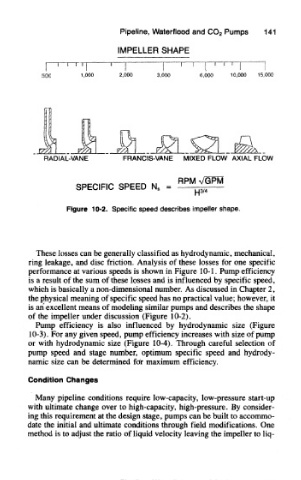

Figure 10-2. Specific speed describes impeller shape.

These losses can be generally classified as hydrodynamic, mechanical,

ring leakage, and disc friction. Analysis of these losses for one specific

performance at various speeds is shown in Figure 10-1. Pump efficiency

is a result of the sum of these losses and is influenced by specific speed,

which is basically a non-dimensional number. As discussed in Chapter 2,

the physical meaning of specific speed has no practical value; however, it

is an excellent means of modeling similar pumps and describes the shape

of the impeller under discussion (Figure 10-2).

Pump efficiency is also influenced by hydrodynamic size (Figure

10-3). For any given speed, pump efficiency increases with size of pump

or with hydrodynamic size (Figure 10-4). Through careful selection of

pump speed and stage number, optimum specific speed and hydrody-

j

namic size can be determined for maximum efficiency.

Condition Changes

Many pipeline conditions require low-capacity, low-pressure start-up

with ultimate change over to high-capacity, high-pressure. By consider-

ing this requirement at the design stage, pumps can be built to accommo-

date the initial and ultimate conditions through field modifications. One

method is to adjust the ratio of liquid velocity leaving the impeller to liq-