Page 166 - Centrifugal Pumps Design and Application

P. 166

Pipeline, Waterflood and CO 2 Pumps 143

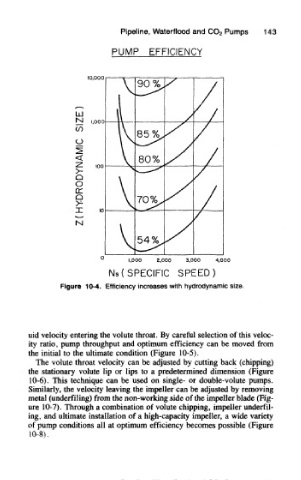

Figure 10-4. Efficiency increases with hydro-dynamic size.

uid velocity entering the volute throat. By careful selection of this veloc-

ity ratio, pump throughput and optimum efficiency can be moved from

the initial to the ultimate condition (Figure 10-5).

The volute throat velocity can be adjusted by cutting back (chipping)

the stationary volute lip or lips to a predetermined dimension (Figure

10-6). This technique can be used on single- or double-volute pumps.

Similarly, the velocity leaving the impeller can be adjusted by removing

metal (underfiling) from the non-working side of the impeller blade (Fig-

ure 10-7). Through a combination of volute chipping, impeller underfil-

ing, and ultimate installation of a high-capacity impeller, a wide variety

of pump conditions all at optimum efficiency becomes possible (Figure

10-8).