Page 223 - Centrifugal Pumps Design and Application

P. 223

High Speed Pumps 19?

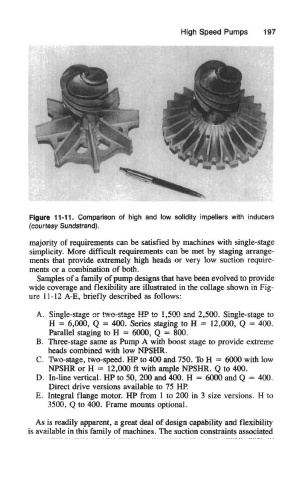

Figure 11-11. Comparison of high and low solidity impellers with inducers

(courtesy Sundstrand).

majority of requirements can be satisfied by machines with single-stage

simplicity. More difficult requirements can be met by staging arrange-

ments that provide extremely high heads or very low suction require-

ments or a combination of both.

Samples of a family of pump designs that have been evolved to provide

wide coverage and flexibility are illustrated in the collage shown in Fig-

ure 11-12 A-E, briefly described as follows:

A. Single-stage or two-stage HP to 1,500 and 2,500. Single-stage to

H = 6,000, Q = 400. Series staging to H = 12,000, Q = 400.

Parallel staging to H = 6000, Q - 800.

B. Three-stage same as Pump A with boost stage to provide extreme

heads combined with low NPSHR.

C. Two-stage, two-speed. HP to 400 and 750. To H = 6000 with low

NPSHR or H = 12,000 ft with ample NPSHR. Q to 400.

D. In-line vertical. HP to 50, 200 and 400. H = 6000 and Q = 400,

Direct drive versions available to 75 HP.

E. Integral flange motor. HP from 1 to 200 in 3 size versions. H to

3500, Q to 400. Frame mounts optional.

As is readily apparent, a great deal of design capability and flexibility

is available in this family of machines. The suction constraints associated