Page 227 - Centrifugal Pumps Design and Application

P. 227

High Speed Pumps 201

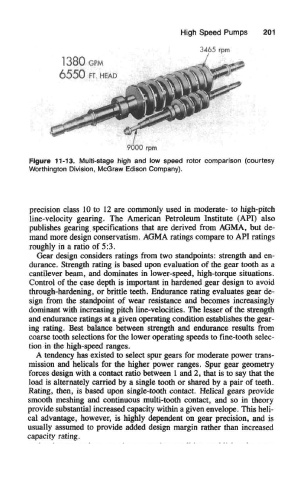

Figure 11-13. Multi-stage high and low speed rotor comparison (courtesy

Worthington Division, McGraw Edison Company).

precision class 10 to 12 are commonly used in moderate- to high-pitch

line-velocity gearing. The American Petroleum Institute (API) also

publishes gearing specifications that are derived from AGMA, but de-

mand more design conservatism. AGMA ratings compare to API ratings

roughly in a ratio of 5:3.

Gear design considers ratings from two standpoints: strength and en-

durance. Strength rating is based upon evaluation of the gear tooth as a

cantilever beam, and dominates in lower-speed, high-torque situations.

Control of the case depth is important in hardened gear design to avoid

through-hardening, or brittle teeth. Endurance rating evaluates gear de-

sign from the standpoint of wear resistance and becomes increasingly

dominant with increasing pitch line-velocities. The lesser of the strength

and endurance ratings at a given operating condition establishes the gear-

ing rating. Best balance between strength and endurance results from

coarse tooth selections for the lower operating speeds to fine-tooth selec-

tion in the high-speed ranges.

A tendency has existed to select spur gears for moderate power trans-

mission and helicals for the higher power ranges. Spur gear geometry

forces design with a contact ratio between 1 and 2, that is to say that the

load is alternately carried by a single tooth or shared by a pair of teeth.

Rating, then, is based upon single-tooth contact. Helical gears provide

smooth meshing and continuous multi-tooth contact, and so in theory

provide substantial increased capacity within a given envelope. This heli-

cal advantage, however, is highly dependent on gear precision, and is

usually assumed to provide added design margin rather than increased

capacity rating.