Page 274 - Centrifugal Pumps Design and Application

P. 274

Slurry Pumps 243

ing the pump speed by changing the sheave ratios. Three to five percent

should be added to the motor BMP to compensate for belt losses. It is

always good practice to add one more belt than is normally calculated to

cover upset conditions and belt breakage.

Motors must be rated with an adequate margin to cover upset condi-

tions such as high flow due to lower-than-expected system losses, higher

concentrations, and start-up. At start-up, the concentration is often

higher, and if the pump was not flushed out during the previous shut-

down, the pump could be plugged with solids requiring high breakaway

torques to get the impeller rotating. This undesirable condition happens

all too frequently and can cause pump damage, excessive wear, and mo-

tor overload.

Under well-controlled systems, free from upset, the motor could be

rated at 20% above the motor shaft BMP; however, this percentage could

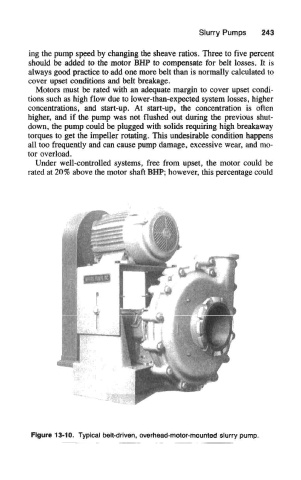

Figure 13-10. Typical belt-driven, overhead-motor-mounted slurry pump.