Page 290 - Centrifugal Pumps Design and Application

P. 290

Hydraulic Power Recovery Turbines 259

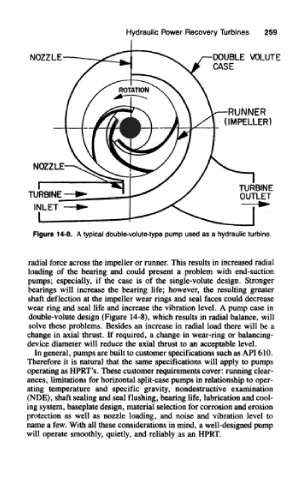

Figure 14-8. A typical double-volute-type pump used as a hydraulic turbine.

radial force across the impeller or runner. This results in increased radial

loading of the bearing and could present a problem with end-suction

pumps; especially, if the case is of the single-volute design. Stronger

bearings will increase the bearing life; however, the resulting greater

shaft deflection at the impeller wear rings and seal faces could decrease

wear ring and seal life and increase the vibration level. A pump case in

double-volute design (Figure 14-8), which results in radial balance, will

solve these problems. Besides an increase in radial load there will be a

change in axial thrust. If required, a change in wear-ring or balancing-

device diameter will reduce the axial thrust to an acceptable level.

In general, pumps are built to customer specifications such as API 610.

Therefore it is natural that the same specifications will apply to pumps

operating as HPRT's, These customer requirements cover: running clear-

ances, limitations for horizontal split-case pumps in relationship to oper-

ating temperature and specific gravity, nondestructive examination

(NDE), shaft sealing and seal flushing, bearing life, lubrication and cool-

ing system, baseplate design, material selection for corrosion and erosion

protection as well as nozzle loading, and noise and vibration level to

name a few. With all these considerations in mind, a well-designed pump

will operate smoothly, quietly, and reliably as an HPRT.