Page 86 - Centrifugal Pumps Design and Application

P. 86

68 Centrifugal Pumps: Design and Application

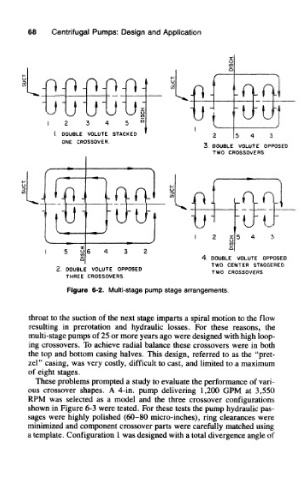

Figure 6-2. Multi-stage pump stage arrangements.

throat to the suction of the next stage imparts a spiral motion to the flow

resulting in prerotation and hydraulic losses. For these reasons, the

multi-stage pumps of 25 or more years ago were designed with high loop-

ing crossovers. To achieve radial balance these crossovers were in both

the top and bottom casing halves. This design, referred to as the "pret-

zel" casing, was very costly, difficult to cast, and limited to a maximum

of eight stages.

These problems prompted a study to evaluate the performance of vari-

ous crossover shapes. A 4-in. pump delivering 1,200 GPM at 3,550

RPM was selected as a model and the three crossover configurations

shown in Figure 6-3 were tested. For these tests the pump hydraulic pas-

sages were highly polished (60-80 micro-inches), ring clearances were

minimized and component crossover parts were carefully matched using

a template. Configuration 1 was designed with a total divergence angle of