Page 146 - Chalcogenide Glasses for Infrared Optics

P. 146

Conventional Lens Fabrication and Spherical Surfaces 123

5.4 Testing

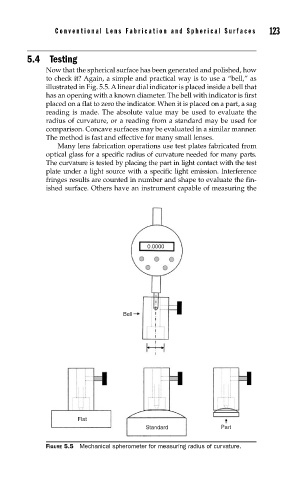

Now that the spherical surface has been generated and polished, how

to check it? Again, a simple and practical way is to use a “bell,” as

illustrated in Fig. 5.5. A linear dial indicator is placed inside a bell that

has an opening with a known diameter. The bell with indicator is first

placed on a flat to zero the indicator. When it is placed on a part, a sag

reading is made. The absolute value may be used to evaluate the

radius of curvature, or a reading from a standard may be used for

comparison. Concave surfaces may be evaluated in a similar manner.

The method is fast and effective for many small lenses.

Many lens fabrication operations use test plates fabricated from

optical glass for a specific radius of curvature needed for many parts.

The curvature is tested by placing the part in light contact with the test

plate under a light source with a specific light emission. Interference

fringes results are counted in number and shape to evaluate the fin-

ished surface. Others have an instrument capable of measuring the

0.0000

Bell

Flat

Standard Part

FIGURE 5.5 Mechanical spherometer for measuring radius of curvature.