Page 198 - Chalcogenide Glasses for Infrared Optics

P. 198

174 Cha pte r Se v e n

Monitor cure: DEFT self-priming topcoat

On application

Absorbance

Fully cured

3500 3000 2500 2000 1500

–1

Wavenumber (cm )

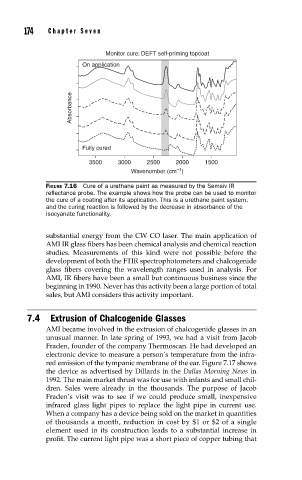

FIGURE 7.16 Cure of a urethane paint as measured by the Semsiv IR

refl ectance probe. The example shows how the probe can be used to monitor

the cure of a coating after its application. This is a urethane paint system,

and the curing reaction is followed by the decrease in absorbance of the

isocyanate functionality.

substantial energy from the CW CO laser. The main application of

AMI IR glass fibers has been chemical analysis and chemical reaction

studies. Measurements of this kind were not possible before the

development of both the FTIR spectrophotometers and chalcogenide

glass fibers covering the wavelength ranges used in analysis. For

AMI, IR fibers have been a small but continuous business since the

beginning in 1990. Never has this activity been a large portion of total

sales, but AMI considers this activity important.

7.4 Extrusion of Chalcogenide Glasses

AMI became involved in the extrusion of chalcogenide glasses in an

unusual manner. In late spring of 1993, we had a visit from Jacob

Fraden, founder of the company Thermoscan. He had developed an

electronic device to measure a person’s temperature from the infra-

red emission of the tympanic membrane of the ear. Figure 7.17 shows

the device as advertised by Dillards in the Dallas Morning News in

1992. The main market thrust was for use with infants and small chil-

dren. Sales were already in the thousands. The purpose of Jacob

Fraden’s visit was to see if we could produce small, inexpensive

infrared glass light pipes to replace the light pipe in current use.

When a company has a device being sold on the market in quantities

of thousands a month, reduction in cost by $1 or $2 of a single

element used in its construction leads to a substantial increase in

profit. The current light pipe was a short piece of copper tubing that