Page 254 - Chalcogenide Glasses for Infrared Optics

P. 254

AMI Infrar ed Crystalline Materials 229

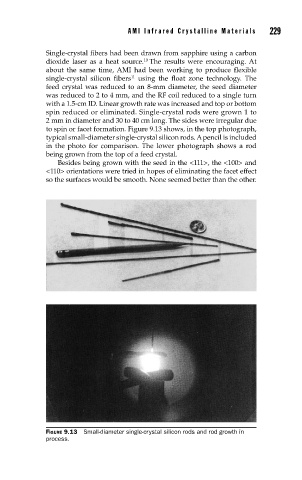

Single-crystal fibers had been drawn from sapphire using a carbon

10

dioxide laser as a heat source. The results were encouraging. At

about the same time, AMI had been working to produce flexible

11

single-crystal silicon fibers using the float zone technology. The

feed crystal was reduced to an 8-mm diameter, the seed diameter

was reduced to 2 to 4 mm, and the RF coil reduced to a single turn

with a 1.5-cm ID. Linear growth rate was increased and top or bottom

spin reduced or eliminated. Single-crystal rods were grown 1 to

2 mm in diameter and 30 to 40 cm long. The sides were irregular due

to spin or facet formation. Figure 9.13 shows, in the top photograph,

typical small-diameter single-crystal silicon rods. A pencil is included

in the photo for comparison. The lower photograph shows a rod

being grown from the top of a feed crystal.

Besides being grown with the seed in the <111>, the <100> and

<110> orientations were tried in hopes of eliminating the facet effect

so the surfaces would be smooth. None seemed better than the other.

FIGURE 9.13 Small-diameter single-crystal silicon rods and rod growth in

process.