Page 259 - Chalcogenide Glasses for Infrared Optics

P. 259

234 Cha pte r Ni ne

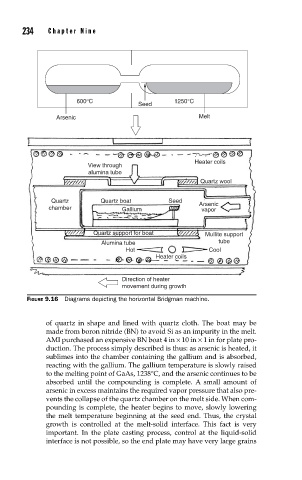

600°C 1250°C

Seed

Arsenic Melt

Heater coils

View through

alumina tube

Quartz wool

Quartz Quartz boat Seed

chamber Gallium Arsenic

vapor

Quartz support for boat Mullite support

Alumina tube tube

Hot Cool

Heater coils

Direction of heater

movement during growth

FIGURE 9.16 Diagrams depicting the horizontal Bridgman machine.

of quartz in shape and lined with quartz cloth. The boat may be

made from boron nitride (BN) to avoid Si as an impurity in the melt.

AMI purchased an expensive BN boat 4 in × 10 in × 1 in for plate pro-

duction. The process simply described is thus: as arsenic is heated, it

sublimes into the chamber containing the gallium and is absorbed,

reacting with the gallium. The gallium temperature is slowly raised

to the melting point of GaAs, 1238°C, and the arsenic continues to be

absorbed until the compounding is complete. A small amount of

arsenic in excess maintains the required vapor pressure that also pre-

vents the collapse of the quartz chamber on the melt side. When com-

pounding is complete, the heater begins to move, slowly lowering

the melt temperature beginning at the seed end. Thus, the crystal

growth is controlled at the melt-solid interface. This fact is very

important. In the plate casting process, control at the liquid-solid

interface is not possible, so the end plate may have very large grains