Page 261 - Chalcogenide Glasses for Infrared Optics

P. 261

236 Cha pte r Ni ne

9

10 6 10 7 10 8 10 10 10 10 11 10 12 10 13 10 14 10 15 10 16 10 17 10 18 10 19

10 9 10 9

10 8 10 8

10 7 10 7

10 6 5 10 6 5

Resistivity (Ω·cm) (log) 10 4 3 2 10 4 3 2 Resistivity (Ω · cm) (log)

10

10

10

10

10

10

10

1

1 10

10 –1 10 –1

10 –2 10 –2

10 –3 10 –3

10 –4 10 –4

9

10 6 10 7 10 8 10 10 10 10 11 10 12 10 13 10 14 10 15 10 16 10 17 10 18 10 19

3

Carrier concentration/cm (log)

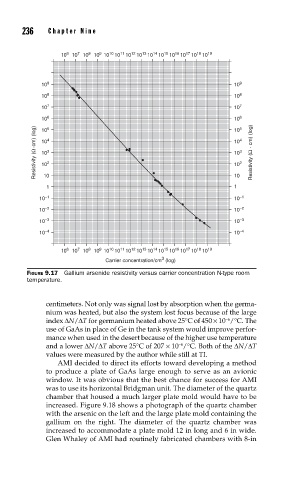

FIGURE 9.17 Gallium arsenide resistivity versus carrier concentration N-type room

temperature.

centimeters. Not only was signal lost by absorption when the germa-

nium was heated, but also the system lost focus because of the large

index ∆N/∆T for germanium heated above 25°C of 450 × 10 /°C. The

−6

use of GaAs in place of Ge in the tank system would improve perfor-

mance when used in the desert because of the higher use temperature

−6

and a lower ∆N/∆T above 25°C of 207 × 10 /°C. Both of the ∆N/∆T

values were measured by the author while still at TI.

AMI decided to direct its efforts toward developing a method

to produce a plate of GaAs large enough to serve as an avionic

window. It was obvious that the best chance for success for AMI

was to use its horizontal Bridgman unit. The diameter of the quartz

chamber that housed a much larger plate mold would have to be

increased. Figure 9.18 shows a photograph of the quartz chamber

with the arsenic on the left and the large plate mold containing the

gallium on the right. The diameter of the quartz chamber was

increased to accommodate a plate mold 12 in long and 6 in wide.

Glen Whaley of AMI had routinely fabricated chambers with 8-in