Page 262 - Chalcogenide Glasses for Infrared Optics

P. 262

AMI Infrar ed Crystalline Materials 237

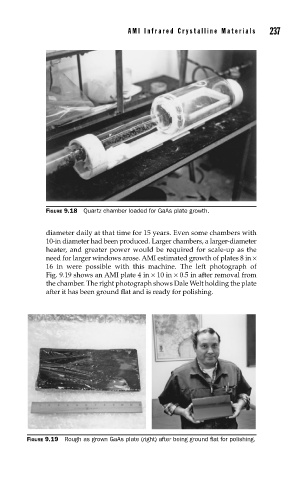

FIGURE 9.18 Quartz chamber loaded for GaAs plate growth.

diameter daily at that time for 15 years. Even some chambers with

10-in diameter had been produced. Larger chambers, a larger-diameter

heater, and greater power would be required for scale-up as the

need for larger windows arose. AMI estimated growth of plates 8 in ×

16 in were possible with this machine. The left photograph of

Fig. 9.19 shows an AMI plate 4 in × 10 in × 0.5 in after removal from

the chamber. The right photograph shows Dale Welt holding the plate

after it has been ground flat and is ready for polishing.

FIGURE 9.19 Rough as grown GaAs plate (right) after being ground fl at for polishing.