Page 287 - Challenges in Corrosion Costs Causes Consequences and Control(2015)

P. 287

DRINKING WATER AND SEWER SYSTEMS 265

Transportation of coal presents a problem because when mixed with moisture, it

becomes highly acidic and corrosive to the carbon steel. A large number of cars are

prone to this corrosion problem. Corrosion is likely to advance further because of the

thawing sheds during the winter months in cold climates in which the cars are heated

to thaw the coal. It is estimated that about 100,000 cars are used in coal service leading

to severe corrosion problems.

Another corrosive is rock salt, which, when transported, causes severe corrosion

that can last for 3 years. The high cost of rehabilitation of salt cars created a trend

toward using unlined, covered hopper cars previously used for transporting grain for

rock salt service. The cars were scrapped when the corrosion was excessive.

To tolerate the properties of cargo, in addition to using linings and coatings, cer-

tain components of the cars, such as valves, undergo an upgrade from the lower

corrosion-resistant carbon steel to the higher-resistant steel grades, such as stainless

steel.

Rubber linings are often used in handling strong acids such as hydrochloric and

phosphoric acids. In the case of extremely aggressive nitric acid, the entire tank body

is made of type 316L stainless steel.

4.18 DRINKING WATER AND SEWER SYSTEMS

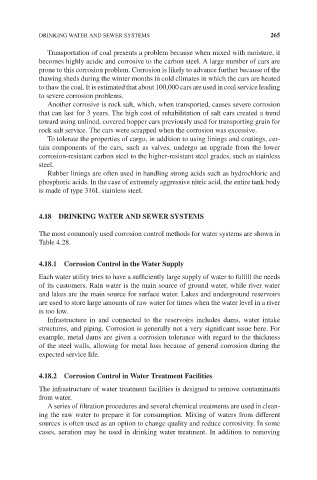

The most commonly used corrosion control methods for water systems are shown in

Table 4.28.

4.18.1 Corrosion Control in the Water Supply

Each water utility tries to have a sufficiently large supply of water to fulfill the needs

of its customers. Rain water is the main source of ground water, while river water

and lakes are the main source for surface water. Lakes and underground reservoirs

are used to store large amounts of raw water for times when the water level in a river

is too low.

Infrastructure in and connected to the reservoirs includes dams, water intake

structures, and piping. Corrosion is generally not a very significant issue here. For

example, metal dams are given a corrosion tolerance with regard to the thickness

of the steel walls, allowing for metal loss because of general corrosion during the

expected service life.

4.18.2 Corrosion Control in Water Treatment Facilities

The infrastructure of water treatment facilities is designed to remove contaminants

from water.

A series of filtration procedures and several chemical treatments are used in clean-

ing the raw water to prepare it for consumption. Mixing of waters from different

sources is often used as an option to change quality and reduce corrosivity. In some

cases, aeration may be used in drinking water treatment. In addition to removing