Page 33 - Challenges in Corrosion Costs Causes Consequences and Control(2015)

P. 33

GALVANIC CORROSION 11

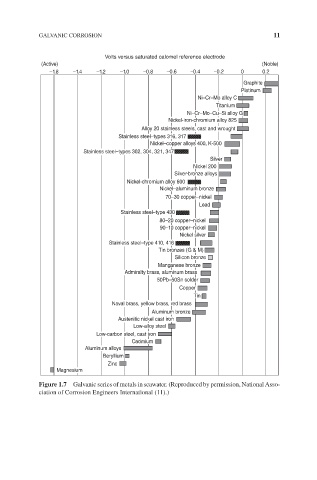

Volts versus saturated calomel reference electrode

(Active) (Noble)

–1.8 –1.4 –1.2 –1.0 –0.8 –0.6 –0.4 –0.2 0 0.2

Graphite

Platinum

Ni–Cr–Mo alloy C

Titanium

Ni–Cr–Mo–Cu–Si alloy G

Nickel-iron-chromium alloy 825

Alloy 20 stainless steels, cast and wrought

Stainless steel–types 316, 317

Nickel–copper alloys 400, K-500

Stainless steel–types 302, 304, 321, 347

Silver

Nickel 200

Silver-bronze alloys

Nickel-chromium alloy 600

Nickel–aluminum bronze

70–30 copper–nickel

Lead

Stainless steel–type 430

80–20 copper–nickel

90–10 copper–nickel

Nickel silver

Stainless steel–type 410, 416

Tin bronzes (G & M)

Silicon bronze

Manganese bronze

Admiralty brass, aluminum brass

50Pb–50Sn solder

Copper

Tin

Naval brass, yellow brass, red brass

Aluminum bronze

Austenitic nickel cast iron

Low-alloy steel

Low-carbon steel, cast iron

Cadmium

Aluminum alloys

Beryllium

Zinc

Magnesium

Figure 1.7 Galvanic series of metals in seawater. (Reproduced by permission, National Asso-

ciation of Corrosion Engineers International (11).)