Page 357 - Challenges in Corrosion Costs Causes Consequences and Control(2015)

P. 357

CORROSION DAMAGE, DEFECTS, AND FAILURES 335

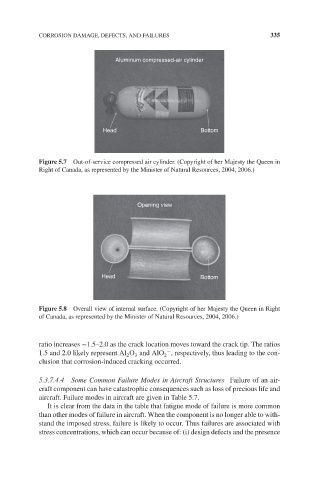

Aluminum compressed-air cylinder

Head Bottom

Figure 5.7 Out-of-service compressed air cylinder. (Copyright of her Majesty the Queen in

Right of Canada, as represented by the Minister of Natural Resources, 2004, 2006.)

Opening view

Head Bottom

Figure 5.8 Overall view of internal surface. (Copyright of her Majesty the Queen in Right

of Canada, as represented by the Minister of Natural Resources, 2004, 2006.)

ratio increases ∼1.5–2.0 as the crack location moves toward the crack tip. The ratios

−

1.5 and 2.0 likely represent Al O and AlO , respectively, thus leading to the con-

2

3

2

clusion that corrosion-induced cracking occurred.

5.3.7.4.4 Some Common Failure Modes in Aircraft Structures Failure of an air-

craft component can have catastrophic consequences such as loss of precious life and

aircraft. Failure modes in aircraft are given in Table 5.7.

It is clear from the data in the table that fatigue mode of failure is more common

than other modes of failure in aircraft. When the component is no longer able to with-

stand the imposed stress, failure is likely to occur. Thus failures are associated with

stress concentrations, which can occur because of: (i) design defects and the presence