Page 115 - Chemical Process Equipment - Selection and Design

P. 115

5.4. SOLID FEEDERS 87

la1

Storage bin

EDER HOUSING

OVABLE OUTER

AIR VENT

ADJUSTABLE INNER

BACK PLATE

\TUM0LER ROD (OPTIONAL)

(e)

Undercut gate - - - -.,

I I

' Cmscfing rod

(i (k)

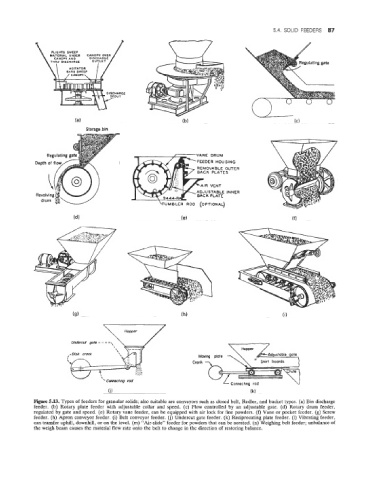

figure 5.13. Types of feeders for granular solids; also suitable are conveyors such as closed belt, Redler, and bucket types. (a) Bin discharge

feeder. (b) Rotary plate feeder with adjustable collar and speed. (c) Flow controlled by an adjustable gate. (d) Rotary drum feeder,

regulated by gate and speed. (e) Rotary vane feeder, can be equipped with air lock for fine powders. (f) Vane or pocket feeder. (g) Screw

feeder. (h) Apron conmeyor feeder. (i) Belt conveyor feeder. (j) Undercut gate feeder. (k) Reciprocating plate feeder. (1) Vibrating feeder,

can transfer uphill, downhill, or on the level. (m) "Air-slide" feeder for powders that can be aerated. (n) Weighing belt feeder; unbalance of

the weigh beam causes the material flow rate onto the belt to change in the direction of restoring balance.