Page 114 - Chemical Process Equipment - Selection and Design

P. 114

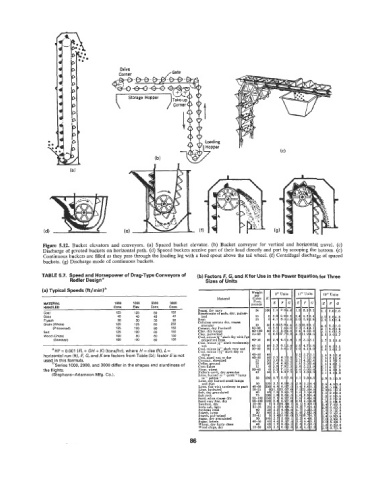

Figure 5.12. Bucket elevators and conveyors. (a) Spaced bucket elevator. (b) Bucket conveyor for vertical and horizontal travel. (c)

Discharge of pivoted buckets on horizontal path. (d) Spaced buckets receive part of their load directly and part by scooping the bottom. (e)

Continuous buckets are filled as they pass through the loading leg with a feed spout above the tail wheel. (f) Centrifugal discharge of spaced

buckets. (g) Discharge mode of continuous buckets.

TABLE 5.7. Speed and Horsepower of Drag-Type Conveyors of (bl Factors F, G, and Kfor Use in the Power Equation for Three

Redler Design" Sizes of Units

(a) Typical Speeds (ft/min)*

19" Unita

itlaterid

E

G

F

MATERIAL 1000 1000 2000 3000 ---

HANDLED Conv. Elev. Conv. Conv.

Beam dry navy 1.1 2.02.6

Coal 125 125 80 150 Bipardanate of soda, dry, pulvw

Coke 40 40 40 40 ,zed 2.2 2.6 4.64.3

5.02.4

Flyash 30 30 30 30 Bran

Grain (Whole) 125 125 80 250 Celluloee acetate dry, cow 4.4 8.52.6

Cement granular dry Portland

(Processed) 125 100 80 150 2.1 4.83.4

Salt 125 100 80 150 Clay. d& lumpy 2.1 4.02.8

Clay pulverized

3.8 9.93.7

Wood (Chips) 100 80 80 150 Coal: minus X" slack dry withl'e

(Sawdust) 100 100 80 150 pmpOltlOn fine3 1.7 3.1 2.6

Coal. minus %" alack moderatel

ret 2.3 4.23.1

Coal minus %" slack very wet 1.8 3.63.2

a HP = 0,001 (FL + GH + K) (tons/hr), where H = rise (ft), L = Coal: minus 1%" slack dry or

damp

horizontal run (ft), F, G, and Kare factors from Table (b); factor E is not Coal, sized wet or dn 1.8 3.32.6

1.5 2.82.4

usedbin this formula. Coconut. ahdded 1.9 3.72.1

1.5 3.02.1

Series 1000,2000, and 3000 differ in the shapes and sturdiness of Coffee. ground 2.1 4 31.7

Corn flakes

the flights. Flour. wheat 2.1 4.32.3

Fuller'a earth dy grand=

2.1 4.44.0

(Stephens-Adamson Mfg. Co.). Lime:<burned'y puisk " lump

2.0 3.53.8

Lige, GbErned small lumpa

and dust 2.5 4.93.6

Lime. fine with tendenoy to paeb 3.0 5.84.1

6.0 18.1 2.83.2 3.8

Lime hydrated 1.5

salt, hry granulated

Salt rock 1.5 2.63.6

Sand. silica co- dry 1.7 3.23.8

Sand very fine, dry 1.9 3.84.0

Sawdust dry 3.4 7.62.5

Soda ad light

soybean kea1 2.8 1.5 6.63.6

2.8

3.1

Starch lump 1.4 2.52.4

Starch: pulverized 3.4 n.93.4

Supar. dry granulated 2.0 3.94.8

Sugar bmwn 3.0 5.64.1

Wheal. dm fzirly clean 1.2 2.23.0

Wood chips. dry 2.0 3.7 1.9

86