Page 109 - Chemical Process Equipment - Selection and Design

P. 109

5.3. MECHANICAL CONVEYORS AND ELEVATORS 81

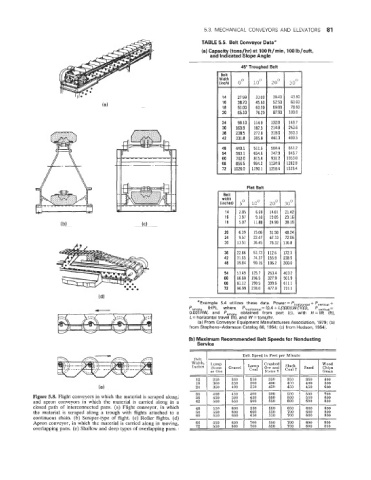

TABLE 5.5. Belt Conveyor Dataa

(a) Capacity (tons/hr) at 100 ft/min, 100 Ib/cuR,

and indicated Slope Angle

45" Troughed Belt

Flat Belt

a Example 5.4 utilizes these data. Power = Phorironta, Pven,ca, +

~

~~

+

P,,, (HP), where Phorironte, (0.4+ ~/3OO)(W/1OOL PVemica,

=

=

O.OOl%, and P,,, obtained from part IC), with H=lift (ft),

L= horizontal travel &, and W= tons/hr.

(a) From Conveyor Equipment Manufacturers Association, 1979; (b)

from Stephens-Adamson Catalog 66, 1954; IC) from Hudson, 19541.

(b) Maximum Recommended Belt Speeds for Mondusting

Service

Belt Speed in Feet per Minute

nelt

12 250 300

18 300 350

350

400

24

Eel -~-

Figure 5.8. Flnght conveyors in which the material is scraped along, 30 400 450

36

500

450

and apron conveyors in which the material is carried along in a 42 500 550

closed path of interconnected pans. (a) Flight conveyor, in which

the material is scraped along a trough with flights attached to a

continuous chain. (b) Scraper-type of flight. (c) Roller flights. (d)

Apron conveyor, in which the material is carried along in moving,

overlapping pans. (e) Shallow and deep types of overlapping pans.