Page 111 - Chemical Process Equipment - Selection and Design

P. 111

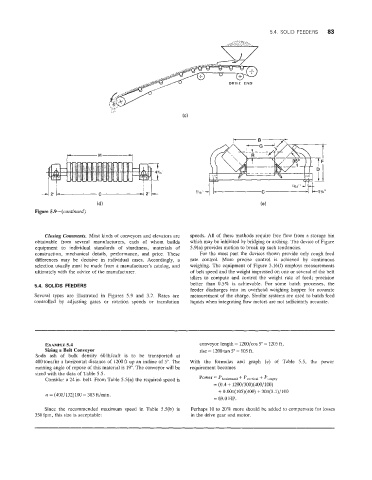

5.4. SOLID FEEDERS 83

.,::.: .:;::?.?.:...

'.. .... . ..._.. .>-.-.:.

. ....

. ..

..

Closing Comments. Most kinds of conveyors and elevators are speeds. All of these methods require free flow from a storage bin

obtainable from several manufacturers, each of whom builds which may be inhibited by bridging or arching. The device of Figure

equipment to individual standards of sturdiness, materials of 5.9(a) provides motion to break up such tendencies.

construction, mechanical details, performance, and price. These For the most part the devices shown provide only rough feed

differences may be decisive in individual cases. Accordingly, a rate control. More precise control is achieved by continuous

selection usually must be made from a manufacturer's catalog, and weighing. The equipment of Figure 3.16(1) employs measurements

ultimately with the advice of the manufacturer. of belt speed and the weight impressed on one or several of the belt

idlers to compute and control the weight rate of feed; precision

better than 0.5% is achievable. For some batch processes, the

feeder discharges into an overhead weighing hopper for accurate

Several types are illustrated in Figures 5.9 and 3.7. Rates are measurement of the charge. Similar systems are used to batch feed

controlled by adjusting gates or rotation speeds or translation liquids when integrating flow meters are not sufficiently accurate.

5.4

EXAMPLIE conveyor length = 12OO/cos 5" = 1205 ft,

Sizing a Belt Conneyor rise = 1200 tan 5" = 105 ft.

Soda ash of bulk density 60lb/cuft is to be transported at

400 tons/hr a horizontal distance of 1200 ft up an incline of 5". The With the formulas and graph (c) of Table 5.5, the power

running angle of repose of this material is 19". The conveyor will be requirement becomes

sized with the data of Table 5.5.

Considel. a 24 in. belt. From Table 5.5(a) the required speed is Power = Phorizontal+ Pvertical+ Pernpty

= (0.4 + 1200/300)(400/100)

+ 0.001(105)(400) + 303(3.1)/100

u = (40C1/132)100 = 303 ft/min.

= 69.0 HP.

Since the recommended maximum speed in Table 5.5(b) is Perhaps 10 to 20% more should be added to compensate for losses

350 fpm, this size is acceptable: in the drive gear and motor.