Page 107 - Chemical Process Equipment - Selection and Design

P. 107

5.3. MECHANICAL CONVEYORS AND ELEVATORS 7

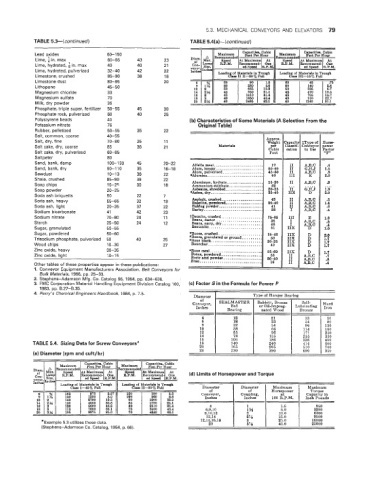

TABLE 5.3-(confinued) TABLE 5.4(a)-( continued)

Lead oxides 60-150

Lime, tin. mar 60-65 43 23

Lime, hydrated, f in. max 40 40 21

Lime, hydrated, pulverized 32-40 42 22

Limestone, crushed 85-90 38 18

Limestone dust 80-85 20

Lithopone 45-50

Magnesium chloride 33

Magnesium sulfate 70

Milk, dry powder 36

Phosphate, triple super, fertilizer 50-55 45 30

Phosphate rock, pulverized 60 40 25

Polystyrene beads 40 (b) Characteristics of Some Materials (A Selection From the

Potassium nitrate 76 Original Table)

-

Rubber, pelletized 50-55 35 22 -

Salt, common, coarse 40-55

Salt, dry, fine 70-80 25 11 Eorae-

Salt cake, dry, coarse 85 36 21 €E&

Salt cake, dry, pulverized 60-85 "E"'

-

Saltpeter 80 -

Sand, bank, damp 100-130 45 20-22 Alfalfa meal. ........................ .4

Sand, bank, dry 90-110 35 16-18 Alum, lumpy.. ...................... 1.6

Alum, pulverized. ...................

.8

Sawdust 10-13 36 22 *Alumina ............................ 2.0

Shale, crushed 85-90 39 22 Aluminum, hydrate. ................. 15-20

1

Soap chips 15-26 30 18 Ammonium sulphate.. ............... 52 ....

1.0

Askh. studded.. ................. 20-25

Soap powder 20-25 'Asbea. dry.. ........................ 55-40 2.0

Soda ash briquetts 50 22 7 Aaphalt. crushed.. ...................

.K

Soda ash, heavy 55-65 32 19 Bakelite, powderad.. ................. 1.4

Soda ash, light 20-35 37 22 Bakhr powder.. .................... .6

Barley.. ............................

Sodium bicarbonate 41 42 23 .4

Sodium nitrate 70-80 24 11 1.8

Starch 25-50 24 12 .5

.4

Sugar, granulated 50-55 1.0

Sugar, powdered 50-60 20

Trisodium phosphate, pulverized 50 40 25 1.7

Wood chips 10-30 27 1.7

1.7

Zinc oxide, heavy 30-35 1.7

Zinc oxide, light 10-15 .7

.8

A

-

Other tables of these properties appear in ,these publications: -

'1. Conveyor E(quipment Manufacturers Association, Belt Conveyors for

Bulk Materials, 1966, pp. 25-33.

2. Stephens-Adamson Mfg. Co. Catalog 66, 1954, pp. 634-636.

3. FNIC Corporation Material Handling Equipment Division Catalog 100, [c) Factor Sin the Formula for Power P

1983, pp. 8.27-8.35.

4. Perry's Chemical Engineers ffandbook, 1984, p. 7.5.

21 33 50

33 54 80

54 96

TABLE 5.4. Sizing Data for Screw Conveyorsa

(a) Diameter [rpm and cuft/hr) I

(d) Limits of Horsepower and Torque

Diameter Diameter Maximum Maximum

of of I Hors;ywer Torque

Conveyor, Coupling. I& Ca acityin Pounds

Inches Inches 100 R.P.M.

"Example 5.3 utilizes these data.

(Stephens-Adarnson Co. Catalog, 1954, p. 66).