Page 108 - Chemical Process Equipment - Selection and Design

P. 108

80 TRANSFER OF SOLIDS

Shear pin

(a)

(b) (C)

(d) (e)

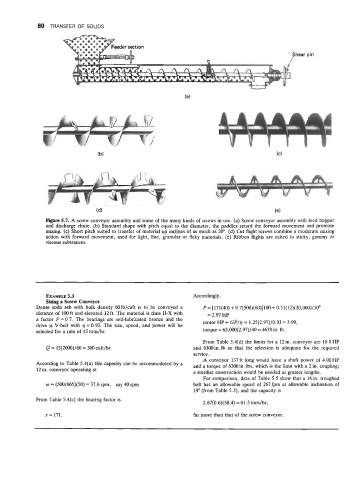

Figpre 5.7. A screw conveyor assembly and some of the many kinds of screws in use. (a) Screw conveyor assembly with feed hopper

and discharge chute. (b) Standard shape with pitch equal to the diameter, the paddles retard the forward movement and promote

mixing. (c) Short pitch suited to transfer of material up inclines of as much as 20". (d) Cut flight screws combine a moderate mixing

action with forward movement, used for light, fine, granular or flaky materials. (e) Ribbon flights are suited to sticky, gummy or

viscous substances.

EXAMPLE 53 Accordingly,

Siig a !hew Conveyor

Dense soda ash with bulk density 60Ib/cuft is to be conveyed a I; = [171(40) + 0.7(500)(60)]100 + 0.51(12)(30,000)/106

distance of 100 ft and elevated 12 ft. The material is class 11-X with = 2.97 HP

a factor F = 0.7. The bearings are self-lubricated bronze and the motor Hp= GP/q = 1.25(2.97)/0.93 = 3.99,

drive is V-belt with 7 = 0.93. The size, speed, and power will be

selected for a rate of 15 tons/hr. torque = 63,000(2.97)/40 = 4678 in. Ib.

From Table 5.4(d) the limits for a 12 in. conveyor are 10.0 HP

Q = 15(2000)/60 = 500 cuft/hr. and 6300in. Ib so that the selection is adequate for the required

service.

A conveyor 137ft long would have a shaft power of 4.00HP

According to Table 5.4(a) this capacity can be accommodated by a and a torque of 6300 in. Ibs, which is the limit with a 2 in. coupling;

12 in. conveyor operating at

a sturdier construction would be needed at greater lengths.

For comparison, data of Table 5.5 show that a 14 in. troughed

w = (500/665)(50) = 37.6 rpm, say 40 rpm belt has an allowable speed of 267fpm at allowable inclination of

19" (from Table 5.3), and the capacity is

From Table 5.4(c) the bearing factor is 2.67(0.6)(38.4) = 61.5 tons/hr,

s = 171. far more than that of the screw conveyor.