Page 365 - Chemical Process Equipment - Selection and Design

P. 365

Cake

Piston

G ilquld Feed funnel

drawoff

Wash pipe

Accessdoor

discharge Spray nozzle

Solids discharge

(a)

arge

(C)

Mechanism for

DRIVING MECHANISM

discharge

_ _ _

I

B 1

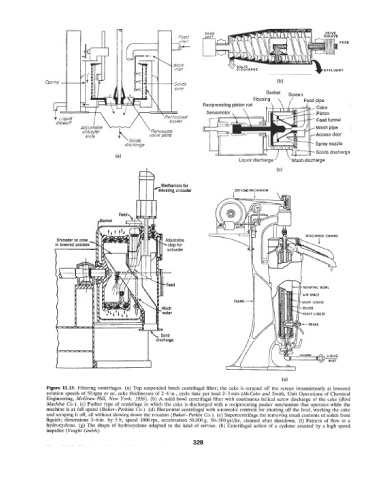

Figure 11.13. Filtering centrifuges. (a) Top suspended batch centrifugal filter; the cake is scraped off the screen intermittently at lowered

rotation speeds of 50 rpm or so, cake thicknesses of 2-6 in., cycle time per load 2-3 min (McCabe and Smith, Unit Operations of Chemical

Engineering, McGraw-Hill, New York, 1956). (b) A solid bowl centrifugal filter with continuous helical screw discharge of the cake (Bird

Machine Co.). (c) Pusher type of centrifuge in which the cake is discharged with a reciprocating pusher mechanism that operates while the

machine is at full speed (Baker-Perkins Co.). (d) Horizontal centrifugal with automatic controls for shutting off the feed, washing the cake

and scraping it off, all without slowing down the rotation (Baker-Perkin Co.). (e) Supercentrifuge for removing small contents of solids from

liquids; dimensions 3-6 in. by 5 ft, speed 1000 rps, acceleration 50,000 g, 50-500 gal/hr, cleaned after shutdown. (f) Pattern of flow in a

hydrocyclone. (9) The shape of hydrocyclone adapted to the kind of service. (h) Centrifugal action of a cyclone assisted by a high speed

impeller (Voight Gmbh).

328