Page 361 - Chemical Process Equipment - Selection and Design

P. 361

324 SOLID-LIQUID SEPARATION

Cloth Plate 7

Frame

Mixture

or wash -

inlet

Head

-Filter cloths Filtrate outlets

(a)

Flltrofe discharge)

manifold

(C)

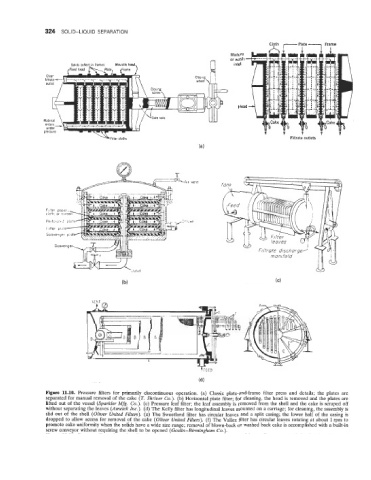

Figure 11.10. Pressure filters for primarily discontinuous operation. (a) Classic plate-and-frame filter press and details; the plates are

separated for manual removal of the cake (T. Shriver Co.). (b) Horizontal plate filter; for cleaning, the head is removed and the plates are

lifted out of the vessel (Sparkler Mfg. Co.). (c) Pressure leaf filter; the leaf assembly is removed from the shell and the cake is scraped off

without separating the leaves (Ametek Znc.). (d) The Kelly filter has longitudinal leaves mounted on a carnage; for cleaning, the assembly is

slid out of the shell (Oliver United Filters). (e) The Sweetland filter has circular leaves and a split casing; the lower half of the casing is

dropped to allow access for removal of the cake (Oliver United Filters). (f) The Vallez filter has circular leaves rotating at about 1 rpm to

promote cake uniformity when the solids have a wide size range; removal of blown-back or washed back cake is accomplished with a built-in

screw conveyor without requiring the shell to be opened (Godin-Birmingham Co.).