Page 358 - Chemical Process Equipment - Selection and Design

P. 358

11.7. APPLICATIONS AND PERFORMANCE OF EQUIPMENT 321

expelled before the bulk of the cake is deposited. Moreover, when

Depth

Sulficlenl the cake is finally deposited from a thickened slurry, it does so with

To Hold Slurry

Wol. For Ome Tes an open structure that allows rapid filtration. A similar factor is

operative in belt or top feed drum filters in which the coarse

particles drop out first and thus form the desirable open structure.

A review of such methods of enhancement of filtration rates is by

Svarovsky (1981).

The relative suitability of the common kinds of solid-liquid

separation equipment is summarized in Table 11.3. Filtration is the

To Gas most frequently used operation, but sedimentation as a method of

Meter pretreatment and centrifugation for difficulty filterable materials has

many applications. Table 11.15 gives more detail about the kinds of

filters appropriate to particular services.

Representative commercial sizes of some types of pressure

filters for operation in batch modes are reported in Table 11.11.

Some of these data are quite old, and not all of the equipment is

currently popular; thus manufacturers should be consulted for the

latest information. Commercially available size ranges of continuous

Gas or air belt, rotary drum, rotary disk, and horizontal rotary filters are listed

pressure

in Table 11.12. For the most part these devices operate with vacua

of 500 Torr or less.

Sedimentation equipment is employed on a large scale for

mineral and ore processing. These and other applications are listed

in Table 11.9(a). The clarification operations of Table 11.9(b) are

Jacket of water cleaning and sewage treatment. The sludges that are

ou+lek- formed often are concentrated further by filtration. Such

I-

applications are listed in Table 11.16 along with other common

applications of plate-and-frame filter presses. Sludge filter cakes are

compressible and have high resistivity so that the elevated pressures

at which presses can be operated are necessary for them. Among

the kinds of data given here are modes of conditioning the slurries,

slurry concentrations, cake characteristics, and cycle times.

Clarification of a great variety of industrial liquids is

accomplished on smaller scales than in tank clarifiers by application

of cartridge filters; some of these applications are listed in Table

Therm 11.10.

Cycle times, air rates, and minimum cake thicknesses in

operation of rotary drum filters are stated in Table 11.13. A few

special applications of horizontal belt filters are given in Table 11.14,

but in recent times this kind of equipment is taking over many of

the traditional functions of rotary drum filters. Belt filters are

favored particularly for freely filtering slurries with wide range of

'Filter cake I Fil particle sizes.

The applications listed in Table 11.17 and 11.18 are a few of

s . 1 Jackist inlet those of rotary drum, rotary disk, and tipping or tilting pan filters.

(b)

Drain The last type employs a number of vacuum pans on a rotating

circular track; after the cake is formed, the pans are blown back

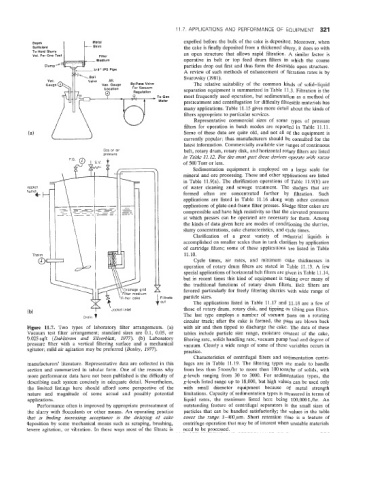

Figure 11.7. Two types of laboratory filter arrangements. (a) with air and then tipped to discharge the cake. The data of these

Vacuum test filter arrangement; standard sizes are 0.1, 0.05, or tables include particle size range, moisture content of the cake,

0.025 sqft (Dahlstrorn and Siluerblutt, 1977). (b) Laboratory filtering rate, solids handling rate, vacuum pump load and degree of

pressure filter with a vertical filtering surface and a mechanical vacuum. Clearly a wide range of s0me of these variables occurs in

agitator; mild air agitation may be preferred (Bosley, 1977).

practice.

Characteristics of centrifugal filters and sedimentation centri-

manufacturers' literature. Representative data are collected in this fuges are in Table 11.19. The filtering types are made to handle

section and summarized in tabular form. One of the reasons why from less than 5 tons/hr to more than 100 tons/hr of solids, with

more performance data have not been published is the difficulty of g-levels ranging from 30 to 3000. For sedimentation types, the

describing each system concisely in adequate detail. Nevertheless, g-levels listed range up to 18,000, but high values can be used only

the limited listmgs here should afford some perspective of the with small diameter equipment because of metal strength

nature and magnitude of some actual and possibly potential limitations. Capacity of sedimentation types is measured in terms of

applications. liquid rates, the maximum listed here being 100,00Q&/hr. An

Performance often is improved by appropriate pretreatment of outstanding feature of centrifugal separators is the small sizes of

the slurry with flocculants or other means. An operating practice particles that can be handled satisfactorily; the values in the table

that is finding increasing acceptance is the delaying of cake cover the range 1-400pm. Short retention time is a feature of

deposition by some mechanical means such as scraping, brushing, centrifuge operation that may be of interest when unstable materials

severe agitation, or vibration. In these ways most of the filtrate is need to be processed.