Page 366 - Chemical Process Equipment - Selection and Design

P. 366

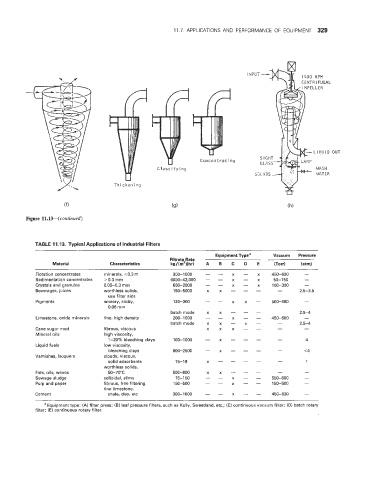

11.7. APPLICATIONS AND PERFORMANCE OF EQUIPMENT

C ENTR I FUGAL

OUT

Coticentrat ing

Classifying

u

Thickening

(f) (h)

Figure ll.B-( continued)

11.1:3. Typical Applications of Industrial Filters

Equipment Type' Vacuum Pressure

Filtrate Rate

Material Characteristics kg/(m2)(hr) A B C D E (Torr) (arm9

Flotation concentrates minerals, <0.3 rn 300-1000 x 450-600

Sedimentation concentrates > 0.3 mm 6000-42,000 x 50-150

Crystals and granules 0.05-0.3 mm 600-2000 x 100-300

Beverages, jLiices worthless solids, 150-5000

use filter aids

Pigments smeary, sticky, 120-300 - 500-680

0.06 mm

batch mode

Limestone. oKide mine!rals fine, high density 200-1000

batch mode

Cane sugar mud fibrous, viscous

Mineral oils high viscosity,

1-20% bleaching clays 100-1000

Liquid fuels low viscosity,

bleaching clays 800-2500

Varnishes, lacquers cloudy, viscous,

solid adsorbents 15-18

worthless solids,

Fats, oils, waxes 50-70°C 500-800 - -

Sewage sludge colloidal, slimy 15-150 - 550-600

Pulp and paper fibrous, free filtering 150-500 - 150-500

fine limestone,

Cement shale, clay, etc 300- 1000 - 450-630

'Equipment type: (A) filter press; (511 leaf pressure filters, such as Kelly, Sweetland, etc.; (C) continuous vacuum filter; (19) batch rotary

filter; (E) continuous rotary filter.