Page 45 - Chemical Process Equipment - Selection and Design

P. 45

20 FLOWSHEETS

Net Fuel Gas 71 83

I c

Sulfur Sulfur

Recovery

Recovery

Primary r-7 Steam + Phenols 2380

I

Steam

Net Waste Liquids

Net Waste Liquids

2380

Carbonizer Primary

Fractionator

Fractionator

Coal

Coal

100,000

Light Aromatics

770

100,000 22,500 Oils Light Aromatics 770

Oils

Recovery

Recovery

Air

Air I I

I I Middle Oils (diesel, etc.) 12575

Middle Oils (diesel, etc.)

12575

Tar Acids 3320

Distillation t Heavy Oils (creosote, etc.) 2380

Pitch

I 1

1 Pitch 3000

Char 77500

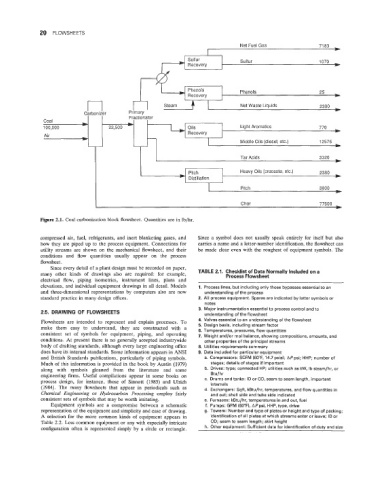

Figure 2.1. Coal carbonization block flowsheet. Quantities are in lb/hr

compressed air, fuel, refrigerants, and inert blanketing gases, and Since a symbol does not usually speak entirely for itself but also

how they are piped up to the process equipment. Connections for carries a name and a letter-number identification, the flowsheet can

utility streams are shown on the mechanical flowsheet, and their be made clear even with the roughest of equipment symbols. The

conditions and flow quantities usually appear on the process

flowsheet.

Since every detail of a plant design must be recorded on paper,

many other kinds of drawings also are required: for example, TABLE 2.1. Checklist of Data Normally Included on a

Process Flowsheet

electrical flow, piping isometrics, instrument lines, plans and

elevations, and individual equipment drawings in all detail. Models 1. Process lines, but including only those bypasses essential to an

and three-dimensional representations by computers also are now understanding of the process

standard practice in many design offices. 2. All process equipment. Spares are indicated by letter symbols or

notes

3. Major instrumentation essential to process control and to

2.5. DRAWING OF FLOWSHEETS understanding of the flowsheet

Flowsheets are intended to represent and explain processes. To 4. Valves essential to an understanding of the flowsheet

make them easy to understand, they are constructed with a 5. Design basis, including stream factor

6. Temperatures, pressures, flow quantities

consistent set of symbols for equipment, piping, and operating 7. Weight and/or mol balance, showing compositions, amounts, and

conditions. At present there is no generally accepted industrywide other properties of the principal streams

body of drafting standards, although every large engineering office 8. Utilities requirements summary

does have its internal standards. Some information appears in ANSI 9. Data included for particular equipment

and British Standards publications, particularly of piping symbols. a. Compressors: SCFM (6OoF, 14.7 psia); APpsi; HHP; number of

Much of this information is provided in the book by Austin (1979) stages; details of stages if important

along with symbols gleaned from the literature and some b. Drives: type; connected HP; utilities such as kW, Ib steam/hr, or

engineering firms. Useful compilations appear in some books on Btu/hr

process design, for instance, those of Sinnott (1983) and Ulrich c. Drums and tanks: ID or OD, seam to seam length, important

internals

(1984). The many flowsheets that appear in periodicals such as d. Exchangers: Sqft, kBtu/hr, temperatures, and flow quantities in

Chemical Engineering or Hydrocarbon Processing employ fairly and out; shell side and tube side indicated

consistent sets of symbols that may be worth imitating. e. Furnaces: kBtu/hr, temperatures in and out, fuel

Equipment symbols are a compromise between a schematic f. Pumps: GPM (60°F), APpsi, HHP, type, drive

representation of the equipment and simplicity and ease of drawing. g. Towers: Number and type of plates or height and type of packing;

A selection for the more common kinds of equipment appears in identification of all plates at which streams enter or leave; ID or

Table 2.2. Less common equipment or any with especially intricate OD; seam to seam length; skirt height

configuration often is represented simply by a circle or rectangle. h. Other equipment: Sufficient data for identification of duty and size