Page 203 - Chemical and process design handbook

P. 203

Speight_Part II_C 11/7/01 3:08 PM Page 2.143

CARBON 2.143

In the thermal black process, natural gas is cracked to carbon black and

o

hydrogen at 1100 to 1650 C in a refractory-lined furnace in a two-cycle

(heating and “making,” or decomposition) operation. The reaction is

CH → C + 2H

4 2

Yields of carbon are in the range 30 to 45 percent.

The gas furnace process, is similar to the oil furnace process but, like

the thermal black process, uses natural gas as feedstock.

Activated carbon is manufactured from carbonaceous materials, such as

petroleum coke, sawdust, lignite, coal, peat, wood, charcoal, nutshells, and

fruit pits. Activation is a physical change wherein the surface of the carbon

is increased by the removal of hydrocarbons by any one of several meth-

ods. The most widely used methods involve treatment of the carbonaceous

material with oxidizing gases such as air, steam, or carbon dioxide, and the

carbonization of the raw material in the presence of chemical agents such

as zinc chloride or phosphoric acid.

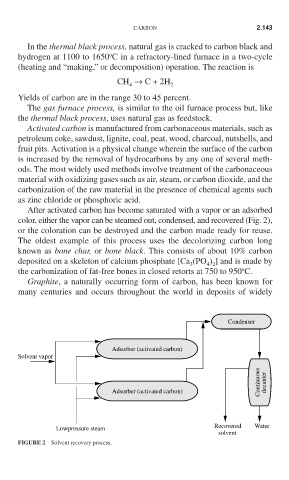

After activated carbon has become saturated with a vapor or an adsorbed

color, either the vapor can be steamed out, condensed, and recovered (Fig. 2),

or the coloration can be destroyed and the carbon made ready for reuse.

The oldest example of this process uses the decolorizing carbon long

known as bone char, or bone black. This consists of about 10% carbon

deposited on a skeleton of calcium phosphate [Ca (PO ) ] and is made by

4 2

3

o

the carbonization of fat-free bones in closed retorts at 750 to 950 C.

Graphite, a naturally occurring form of carbon, has been known for

many centuries and occurs throughout the world in deposits of widely

Condenser

Adsorber (activated carbon)

Solvent vapor

Continuous decanter

Adsorber (activated carbon)

Low-pressure steam Recovered Water

solvent

FIGURE 2 Solvent recovery process.