Page 204 - Chemical and process design handbook

P. 204

Speight_Part II_C 11/7/01 3:08 PM Page 2.144

2.144 MANUFACTURE OF CHEMICALS

varying purity and crystalline size and perfection. For import purposes,

natural graphite is classified as crystalline and amorphous The latter is not

.

truly amorphous but has an imperfect lamellar microcrystalline structure.

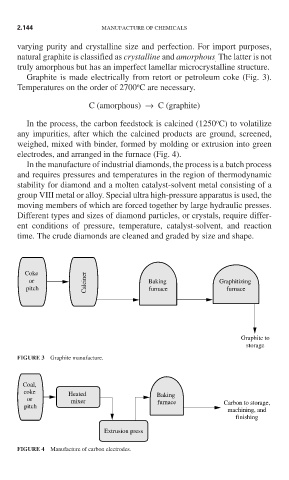

Graphite is made electrically from retort or petroleum coke (Fig. 3).

o

Temperatures on the order of 2700 C are necessary.

C (amorphous) → C (graphite)

o

In the process, the carbon feedstock is calcined (1250 C) to volatilize

any impurities, after which the calcined products are ground, screened,

weighed, mixed with binder, formed by molding or extrusion into green

electrodes, and arranged in the furnace (Fig. 4).

In the manufacture of industrial diamonds, the process is a batch process

and requires pressures and temperatures in the region of thermodynamic

stability for diamond and a molten catalyst-solvent metal consisting of a

group VIII metal or alloy. Special ultra high-pressure apparatus is used, the

moving members of which are forced together by large hydraulic presses.

Different types and sizes of diamond particles, or crystals, require differ-

ent conditions of pressure, temperature, catalyst-solvent, and reaction

time. The crude diamonds are cleaned and graded by size and shape.

Coke

or Calciner Baking Graphitizing

pitch furnace furnace

Graphite to

storage

FIGURE 3 Graphite manufacture.

Coal,

coke Heated Baking

or

mixer furnace Carbon to storage,

pitch

machining, and

finishing

Extrusion press

FIGURE 4 Manufacture of carbon electrodes.