Page 22 - Chemical and process design handbook

P. 22

Speight_Part 1_A 11/7/01 3:04 PM Page 1.8

1.8 REACTION TYPES

immersed in a molten salt bath. The nitrogen that accompanies the gener-

ated hydrogen is inert.

Amination is also achieved by the use of ammonia (NH ), in a process

3

referred to as ammonolysis. An example is the production of aniline

(C H NH ) from chlorobenzene (C H Cl) with ammonia (NH ). The reac-

5

3

6

5

6

2

tion proceeds only under high pressure.

The replacement of a nuclear substituent such as hydroxyl (–OH),

chloro, (–Cl), or sulfonic acid (–SO H) with amino (–NH ) by the use of

3

2

ammonia (ammonolysis) has been practiced for some time with feed-

stocks that have reaction-inducing groups present thereby making

replacement easier. For example, 1,4-dichloro-2-nitrobenzene can be

changed readily to 4-chloro-2-nitroaniline by treatment with aqueous

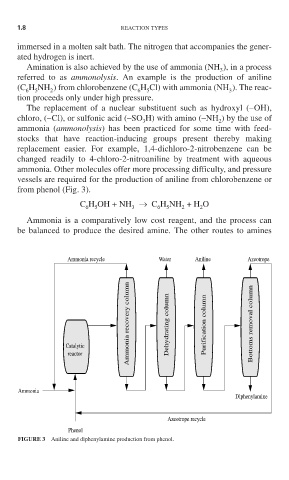

ammonia. Other molecules offer more processing difficulty, and pressure

vessels are required for the production of aniline from chlorobenzene or

from phenol (Fig. 3).

C H OH + NH → C H NH + H O

6 5 3 6 5 2 2

Ammonia is a comparatively low cost reagent, and the process can

be balanced to produce the desired amine. The other routes to amines

Ammonia recycle Water Aniline Azeotrope

Ammonia recovery column Dehydrating column Purification column Bottoms removal column

Catalytic

reactor

Ammonia

Diphenylamine

Azeotrope recycle

Phenol

FIGURE 3 Aniline and diphenylamine production from phenol.