Page 44 - Chemical and process design handbook

P. 44

Speight_Part 1_H 11/7/01 3:03 PM Page 1.30

1.30 REACTION TYPES

Many hydrogenation processes are of a proprietary nature, with numerous

combinations of catalysts, temperature, and pressure possible.

Lower pressures and higher temperatures favor dehydrogenation, but

the catalysts used are the same as for hydrogenation.

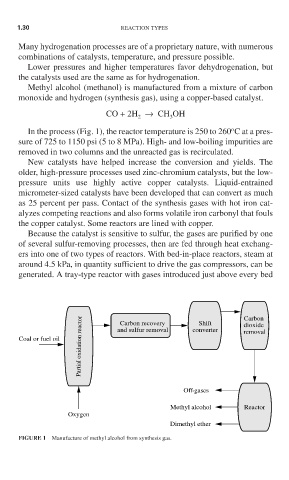

Methyl alcohol (methanol) is manufactured from a mixture of carbon

monoxide and hydrogen (synthesis gas), using a copper-based catalyst.

CO + 2H → CH OH

2 3

o

In the process (Fig. 1), the reactor temperature is 250 to 260 C at a pres-

sure of 725 to 1150 psi (5 to 8 MPa). High- and low-boiling impurities are

removed in two columns and the unreacted gas is recirculated.

New catalysts have helped increase the conversion and yields. The

older, high-pressure processes used zinc-chromium catalysts, but the low-

pressure units use highly active copper catalysts. Liquid-entrained

micrometer-sized catalysts have been developed that can convert as much

as 25 percent per pass. Contact of the synthesis gases with hot iron cat-

alyzes competing reactions and also forms volatile iron carbonyl that fouls

the copper catalyst. Some reactors are lined with copper.

Because the catalyst is sensitive to sulfur, the gases are purified by one

of several sulfur-removing processes, then are fed through heat exchang-

ers into one of two types of reactors. With bed-in-place reactors, steam at

around 4.5 kPa, in quantity sufficient to drive the gas compressors, can be

generated. A tray-type reactor with gases introduced just above every bed

Partial oxidation reactor

Carbon

Shift

Carbon recovery

removal

Coal or fuel oil and sulfur removal converter dioxide

Off-gases

Methyl alcohol Reactor

Oxygen

Dimethyl ether

FIGURE 1 Manufacture of methyl alcohol from synthesis gas.