Page 47 - Chemical and process design handbook

P. 47

Speight_Part 1_N&O 11/7/01 3:02 PM Page 1.33

NITRATION 1.33

Water

Benzene

Nitric acid

Benzene

Washer

Nitrator Separator

Waste Distillation

water

treatment

Fresh Nitrobenzene

sulfuric acid

Sulfuric acid Water

reconcentration

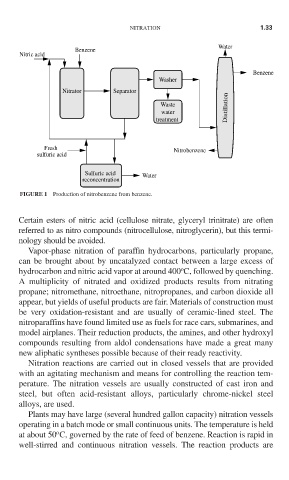

FIGURE 1 Production of nitrobenzene from benzene.

Certain esters of nitric acid (cellulose nitrate, glyceryl trinitrate) are often

referred to as nitro compounds (nitrocellulose, nitroglycerin), but this termi-

nology should be avoided.

Vapor-phase nitration of paraffin hydrocarbons, particularly propane,

can be brought about by uncatalyzed contact between a large excess of

o

hydrocarbon and nitric acid vapor at around 400 C, followed by quenching.

A multiplicity of nitrated and oxidized products results from nitrating

propane; nitromethane, nitroethane, nitropropanes, and carbon dioxide all

appear, but yields of useful products are fair. Materials of construction must

be very oxidation-resistant and are usually of ceramic-lined steel. The

nitroparaffins have found limited use as fuels for race cars, submarines, and

model airplanes. Their reduction products, the amines, and other hydroxyl

compounds resulting from aldol condensations have made a great many

new aliphatic syntheses possible because of their ready reactivity.

Nitration reactions are carried out in closed vessels that are provided

with an agitating mechanism and means for controlling the reaction tem-

perature. The nitration vessels are usually constructed of cast iron and

steel, but often acid-resistant alloys, particularly chrome-nickel steel

alloys, are used.

Plants may have large (several hundred gallon capacity) nitration vessels

operating in a batch mode or small continuous units. The temperature is held

o

at about 50 C, governed by the rate of feed of benzene. Reaction is rapid in

well-stirred and continuous nitration vessels. The reaction products are