Page 51 - Chemical and process design handbook

P. 51

Speight_Part 1_N&O 11/7/01 3:02 PM Page 1.37

OXIDATION 1.37

Several oxidative routes are available to change cyclohexane to cyclo-

hexanone, cyclohexanol, and ultimately to adipic acid or caprolactam. If

phenol is hydrogenated, cyclohexanone can be obtained directly; this will

react with hydroxylamine to give cyclohexanone oxime that converts to

caprolactam on acid rearrangement. Cyclohexane can also be converted to

adipic acid, then adiponitrile, which can be converted to hexamethylenedi-

amine. Adipic acid and hexamethylenediamine are used to form nylon 6,6.

This route to hexamethylenediamine is competitive with alternative routes

through butene.

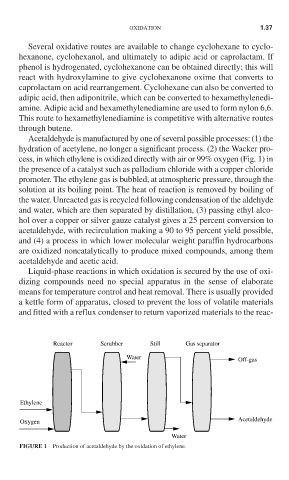

Acetaldehyde is manufactured by one of several possible processes: (1) the

hydration of acetylene, no longer a significant process. (2) the Wacker pro-

cess, in which ethylene is oxidized directly with air or 99% oxygen (Fig. 1) in

the presence of a catalyst such as palladium chloride with a copper chloride

promoter. The ethylene gas is bubbled, at atmospheric pressure, through the

solution at its boiling point. The heat of reaction is removed by boiling of

the water. Unreacted gas is recycled following condensation of the aldehyde

and water, which are then separated by distillation, (3) passing ethyl alco-

hol over a copper or silver gauze catalyst gives a 25 percent conversion to

acetaldehyde, with recirculation making a 90 to 95 percent yield possible,

and (4) a process in which lower molecular weight paraffin hydrocarbons

are oxidized noncatalytically to produce mixed compounds, among them

acetaldehyde and acetic acid.

Liquid-phase reactions in which oxidation is secured by the use of oxi-

dizing compounds need no special apparatus in the sense of elaborate

means for temperature control and heat removal. There is usually provided

a kettle form of apparatus, closed to prevent the loss of volatile materials

and fitted with a reflux condenser to return vaporized materials to the reac-

Reactor Scrubber Still Gas separator

Water

Off-gas

Ethylene

Acetaldehyde

Oxygen

Water

FIGURE 1 Production of acetaldehyde by the oxidation of ethylene.