Page 284 - Chemical engineering design

P. 284

259

COSTING AND PROJECT EVALUATION

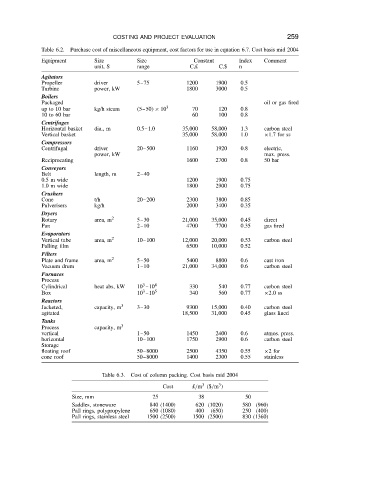

Table 6.2.

Constant

Size

Comment

Size

Index

Equipment Purchase cost of miscellaneous equipment, cost factors for use in equation 6.7. Cost basis mid 2004

unit, S range C,£ C,$ n

Agitators

Propeller driver 5 75 1200 1900 0.5

Turbine power, kW 1800 3000 0.5

Boilers

Packaged oil or gas fired

up to 10 bar kg/h steam 5 50 ð 10 3 70 120 0.8

10 to 60 bar 60 100 0.8

Centrifuges

Horizontal basket dia., m 0.5 1.0 35,000 58,000 1.3 carbon steel

Vertical basket 35,000 58,000 1.0 ð1.7 for ss

Compressors

Centrifugal driver 20 500 1160 1920 0.8 electric,

power, kW max. press.

Reciprocating 1600 2700 0.8 50 bar

Conveyors

Belt length, m 2 40

0.5 m wide 1200 1900 0.75

1.0 m wide 1800 2900 0.75

Crushers

Cone t/h 20 200 2300 3800 0.85

Pulverisers kg/h 2000 3400 0.35

Dryers

Rotary area, m 2 5 30 21,000 35,000 0.45 direct

Pan 2 10 4700 7700 0.35 gas fired

Evaporators

Vertical tube area, m 2 10 100 12,000 20,000 0.53 carbon steel

Falling film 6500 10,000 0.52

Filters

Plate and frame area, m 2 5 50 5400 8800 0.6 cast iron

Vacuum drum 1 10 21,000 34,000 0.6 carbon steel

Furnaces

Process

Cylindrical heat abs, kW 10 3 10 4 330 540 0.77 carbon steel

Box 10 3 10 5 340 560 0.77 ð2.0ss

Reactors

Jacketed, capacity, m 3 3 30 9300 15,000 0.40 carbon steel

agitated 18,500 31,000 0.45 glass lined

Tanks

Process capacity, m 3

vertical 1 50 1450 2400 0.6 atmos. press.

horizontal 10 100 1750 2900 0.6 carbon steel

Storage

floating roof 50 8000 2500 4350 0.55 ð2for

cone roof 50 8000 1400 2300 0.55 stainless

Table 6.3. Cost of column packing. Cost basis mid 2004

3

3

Cost £/m ($/m )

Size, mm 25 38 50

Saddles, stoneware 840 (1400) 620 (1020) 580 (960)

Pall rings, polypropylene 650 (1080) 400 (650) 250 (400)

Pall rings, stainless steel 1500 (2500) 1500 (2500) 830 (1360)