Page 295 - Chemical engineering design

P. 295

270

CHEMICAL ENGINEERING

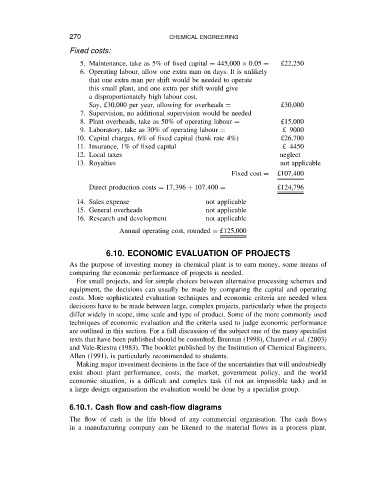

Fixed costs:

5. Maintenance, take as 5% of fixed capital D 445,000 ð 0.05 D £22,250

6. Operating labour, allow one extra man on days. It is unlikely

that one extra man per shift would be needed to operate

this small plant, and one extra per shift would give

a disproportionately high labour cost.

Say, £30,000 per year, allowing for overheads D £30,000

7. Supervision, no additional supervision would be needed

8. Plant overheads, take as 50% of operating labour D £15,000

9. Laboratory, take as 30% of operating labour D £ 9000

10. Capital charges, 6% of fixed capital (bank rate 4%) £26,700

11. Insurance, 1% of fixed capital £ 4450

12. Local taxes neglect

13. Royalties not applicable

Fixed cost D £107,400

Direct production costs D 17,396 C 107,400 D £124,796

14. Sales expense not applicable

15. General overheads not applicable

16. Research and development not applicable

Annual operating cost, rounded D £125,000

6.10. ECONOMIC EVALUATION OF PROJECTS

As the purpose of investing money in chemical plant is to earn money, some means of

comparing the economic performance of projects is needed.

For small projects, and for simple choices between alternative processing schemes and

equipment, the decisions can usually be made by comparing the capital and operating

costs. More sophisticated evaluation techniques and economic criteria are needed when

decisions have to be made between large, complex projects, particularly when the projects

differ widely in scope, time scale and type of product. Some of the more commonly used

techniques of economic evaluation and the criteria used to judge economic performance

are outlined in this section. For a full discussion of the subject one of the many specialist

texts that have been published should be consulted; Brennan (1998), Chauvel et al. (2003)

and Vale-Riestra (1983). The booklet published by the Institution of Chemical Engineers,

Allen (1991), is particularly recommended to students.

Making major investment decisions in the face of the uncertainties that will undoubtedly

exist about plant performance, costs, the market, government policy, and the world

economic situation, is a difficult and complex task (if not an impossible task) and in

a large design organisation the evaluation would be done by a specialist group.

6.10.1. Cash flow and cash-flow diagrams

The flow of cash is the life blood of any commercial organisation. The cash flows

in a manufacturing company can be likened to the material flows in a process plant.