Page 21 - Chemical process engineering design and economics

P. 21

Chapter 1

Plan EWWtkxi Process Design

I————————I——————————————I

6 months 9 months

Plant Design

I————————————I

15 months

Startup Routine Operation Routine Operation

|———|—————————|———+-

3 months «t restricted capacity at design capacity

Debottknecklng

Tlmeftom Conceptlonaf Stage to Routlrw Operation

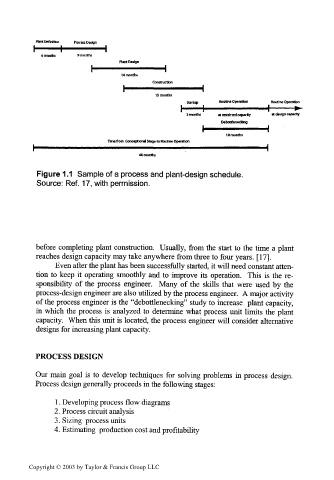

Figure 1.1 Sample of a process and plant-design schedule.

Source: Ref. 17, with permission.

before completing plant construction. Usually, from the start to the time a plant

reaches design capacity may take anywhere from three to four years. [17].

Even after the plant has been successfully started, it will need constant atten-

tion to keep it operating smoothly and to improve its operation. This is the re-

sponsibility of the process engineer. Many of the skills that were used by the

process-design engineer are also utilized by the process engineer. A major activity

of the process engineer is the "debottlenecking" study to increase plant capacity,

in which the process is analyzed to determine what process unit limits the plant

capacity. When this unit is located, the process engineer will consider alternative

designs for increasing plant capacity.

PROCESS DESIGN

Our main goal is to develop techniques for solving problems in process design.

Process design generally proceeds in the following stages:

1. Developing process flow diagrams

2. Process circuit analysis

3. Sizing process units

4. Estimating production cost and profitability

Copyright © 2003 by Taylor & Francis Group LLC