Page 20 - Chemical process engineering design and economics

P. 20

Processes and Process Engineering 7

At the end of the pilot-scale tests, the process is again evaluated, but since

the process-design phase of the project will require a substantial increase in capital

investment, the calculations require improved accuracy. Table 1.2 lists the activi-

ties of the process-design engineer. Usually, there are several technically accept-

able alternatives available for each process unit, so that the process-design engi-

neer will have to evaluate these alternatives to determine the most economical

design. Additionally, each process unit can operate successfully under a variety of

conditions so that the engineer must conduct studies to determine the economi-

cally-optimum operating conditions. It is clear from the foregoing discussion that

economics determines the direction taken at each phase of the project. Conse-

quently, process economics will be discussed in the next chapter. It can also be

seen from Table 1.2 that there are several social aspects of the process design that

must be considered. The effects of any possible emissions on the health of the

workers, the surrounding community, and the environment must be evaluated.

Even aesthetics will have to be considered to a greater extent than has been done

in the past.

The next phase of the project is plant design and construction, which em-

ploys a variety of engineering skills, mainly mechanical, civil, and electrical. The

objective in this phase of the project is to implement the process design. Table 1.2

outlines the major activities of this phase. Most likely a plant design and construc-

tion company will conduct this phase of the project, commonly called outsourcing.

After the plant is constructed, the operations phase of the project begins,

which includes plant startup. Rarely does this operation proceed smoothly. Trou-

bleshooting, process modifications, and repairs are generally required.

Because of the need to get the plant on-stream as soon as possible, the proc-

ess design, plant design, plant construction and plant startup must be completed as

rapidly as possible. Electrical, mechanical or chemical systems, as well as any

human activity need to be controlled or regulated to approach optimum perform-

ance. Similarly, project management, or more appropriately project control, is

needed because of the complexity of process and plant design, and construction.

Numerous activities must be scheduled, coordinated and progress monitored to

complete the project on time. It is the responsibility of the project engineer to plan

and control all activities so that the plant is brought on-stream quickly. It is poor

planning to complete the tasks sequentially, i.e., completing one task before start-

ing another task. To reduce the time from the initiation of a project to routine plant

operation, the strategy is to conduct as many parallel activities as possible. Thus,

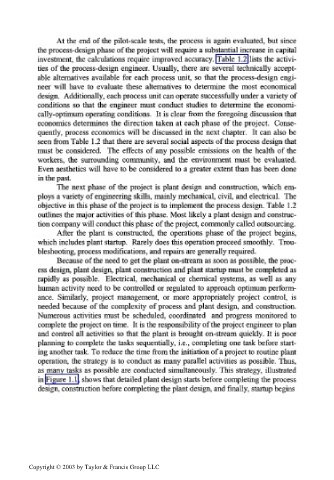

as many tasks as possible are conducted simultaneously. This strategy, illustrated

in Figur e 1.1 , shows that detailed plant design starts before completing the process

design, construction before completing the plant design, and finally, startup begins

Copyright © 2003 by Taylor & Francis Group LLC