Page 15 - Chemical process engineering design and economics

P. 15

Chapter 1

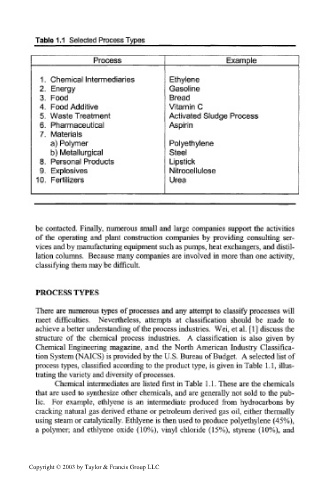

Table 1.1 Selected Process Types

Process Example

1. Chemical Intermediaries Ethylene

2. Energy Gasoline

3. Food Bread

4. Food Additive Vitamin C

5. Waste Treatment Activated Sludge Process

6. Pharmaceutical Aspirin

7. Materials

a) Polymer Polyethylene

b) Metallurgical Steel

8. Personal Products Lipstick

9. Explosives Nitrocellulose

10. Fertilizers Urea

be contacted. Finally, numerous small and large companies support the activities

of the operating and plant construction companies by providing consulting ser-

vices and by manufacturing equipment such as pumps, heat exchangers, and distil-

lation columns. Because many companies are involved in more than one activity,

classifying them may be difficult.

PROCESS TYPES

There are numerous types of processes and any attempt to classify processes will

meet difficulties. Nevertheless, attempts at classification should be made to

achieve a better understanding of the process industries. Wei, et al. [1] discuss the

structure of the chemical process industries. A classification is also given by

Chemical Engineering magazine, and the North American Industry Classifica-

tion System (NAICS) is provided by the U.S. Bureau of Budget. A selected list of

process types, classified according to the product type, is given in Table 1.1, illus-

trating the variety and diversity of processes.

Chemical intermediates are listed first in Table 1.1. These are the chemicals

that are used to synthesize other chemicals, and are generally not sold to the pub-

lic. For example, ethlyene is an intermediate produced from hydrocarbons by

cracking natural gas derived ethane or petroleum derived gas oil, either thermally

using steam or catalytically. Ethlyene is then used to produce polyethylene (45%),

a polymer; and ethlyene oxide (10%), vinyl chloride (15%), styrene (10%), and

Copyright © 2003 by Taylor & Francis Group LLC