Page 291 - Chemical process engineering design and economics

P. 291

270 Chapter 6

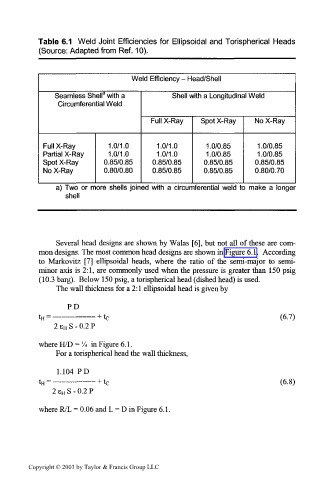

Table 6.1 Weld Joint Efficiencies for Ellipsoidal and Torispherical Heads

(Source: Adapted from Ref. 10).

Weld Efficiency - Head/Shell

3

Seamless Shell with a Shell with a Longitudinal Weld

Circumferential Weld

Full X-Ray Spot X-Ray No X-Ray

Full X-Ray 1.0/1.0 1.0/1.0 1.0/0.85 1.0/0.85

Partial X-Ray 1.0/1.0 1.0/1.0 1.0/0.85 1.0/0.85

Spot X-Ray 0.85/0.85 0.85/0.85 0.85/0.85 0.85/0.85

No X-Ray 0.80/0.80 0.85/0.85 0.85/0.85 0.80/0.70

a) Two or more shells joined with a circumferential weld to make a longer

shell

Several head designs are shown by Walas [6], but not all of these are com-

mon designs. The most common head designs are shown in Figure 6.1. According

to Markovitz [7] ellipsoidal heads, where the ratio of the semi-major to semi-

minor axis is 2:1, are commonly used when the pressure is greater than 150 psig

(10.3 barg). Below 150 psig, a torispherical head (dished head) is used.

The wall thickness for a 2:1 ellipsoidal head is given by

PD

(6.7)

2 e H S - 0.2 P

where H/D = % in Figure 6.1.

For a torispherical head the wall thickness,

1.104 PD

(6.8)

2 s H S - 0.2 P

where R/L = 0.06 and L = D in Figure 6.1.

Copyright © 2003 by Taylor & Francis Group LLC