Page 295 - Chemical process engineering design and economics

P. 295

274 Chapter 6

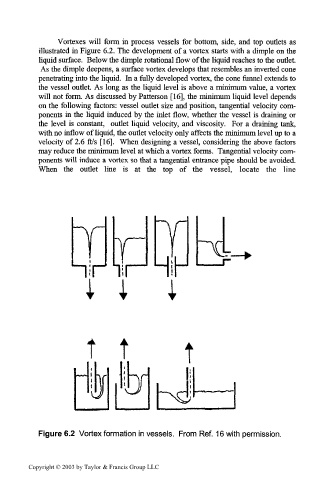

Vortexes will form in process vessels for bottom, side, and top outlets as

illustrated in Figure 6.2. The development of a vortex starts with a dimple on the

liquid surface. Below the dimple rotational flow of the liquid reaches to the outlet.

As the dimple deepens, a surface vortex develops that resembles an inverted cone

penetrating into the liquid. In a fully developed vortex, the cone funnel extends to

the vessel outlet. As long as the liquid level is above a minimum value, a vortex

will not form. As discussed by Patterson [16], the minimum liquid level depends

on the following factors: vessel outlet size and position, tangential velocity com-

ponents in the liquid induced by the inlet flow, whether the vessel is draining or

the level is constant, outlet liquid velocity, and viscosity. For a draining tank,

with no inflow of liquid, the outlet velocity only affects the minimum level up to a

velocity of 2.6 ft/s [16]. When designing a vessel, considering the above factors

may reduce the minimum level at which a vortex forms. Tangential velocity com-

ponents will induce a vortex so that a tangential entrance pipe should be avoided.

When the outlet line is at the top of the vessel, locate the line

Figure 6.2 Vortex formation in vessels. From Ref. 16 with permission.

Copyright © 2003 by Taylor & Francis Group LLC