Page 313 - Chemical process engineering design and economics

P. 313

292 Chapter 6

Round off the length to 6.75 ft (2.06 m). The effect of increasing the separator

length is to increase the surge time above the original 8.75 min.

The vertical separator is 1.625 ft (0.494 m) in diameter and 8.5 ft (2.59 m)

long. At this point, it appears that the vertical separator is the best choice because

of its smaller diameter and wall thickness. Also, locating the mist eliminator out-

side of the separator shell will add to the cost of the horizontal separator.

Liquid-Liquid Separators

Liquid-liquid separators are also called decanters or settlers. The flow to the set-

tler consists of a dispersed phase and a continuous phase, and the function of a

settler is to coalesce and separate the dispersed phase from the continuous phase.

The separator volume must be sufficiently large to allow sufficient time for the

dispersed-phase drops to reach the liquid-liquid interface and coalescence. Thus,

the residence time has two components. These are: the time required for the drop-

lets to reach the interface and the time required for the droplets to coalesce.

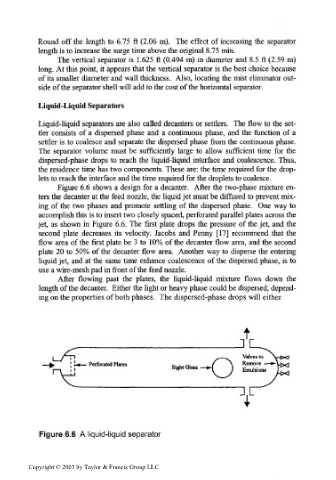

Figure 6.6 shows a design for a decanter. After the two-phase mixture en-

ters the decanter at the feed nozzle, the liquid jet must be diffused to prevent mix-

ing of the two phases and promote settling of the dispersed phase. One way to

accomplish this is to insert two closely spaced, perforated parallel plates across the

jet, as shown in Figure 6.6. The first plate drops the pressure of the jet, and the

second plate decreases its velocity. Jacobs and Penny [17] recommend that the

flow area of the first plate be 3 to 10% of the decanter flow area, and the second

plate 20 to 50% of the decanter flow area. Another way to disperse the entering

liquid jet, and at the same time enhance coalescence of the dispersed phase, is to

use a wire-mesh pad in front of the feed nozzle.

After flowing past the plates, the liquid-liquid mixture flows down the

length of the decanter. Either the light or heavy phase could be dispersed, depend-

ing on the properties of both phases. The dispersed-phase drops will either

———————————————————— . . __^

1 ___ Valves to

1-4 — Perforated Plates . / ^ Remove -

Sight Glass _W J Emulsions

J

———————————————————— . . —— --

Figure 6.6 A liquid-liquid separator

Copyright © 2003 by Taylor & Francis Group LLC