Page 371 - Chemical process engineering design and economics

P. 371

350 Chapter 6

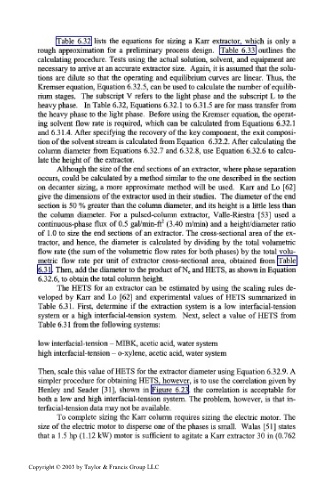

Table 6.32 lists the equations for sizing a Karr extractor, which is only a

rough approximation for a preliminary process design. Table 6.33 outlines the

calculating procedure. Tests using the actual solution, solvent, and equipment are

necessary to arrive at an accurate extractor size. Again, it is assumed that the solu-

tions are dilute so that the operating and equilibrium curves are linear. Thus, the

Kremser equation, Equation 6.32.5, can be used to calculate the number of equilib-

rium stages. The subscript V refers to the light phase and the subscript L to the

heavy phase. In Table 6.32, Equations 6.32.1 to 6.31.5 are for mass transfer from

the heavy phase to the light phase. Before using the Kremser equation, the operat-

ing solvent flow rate is required, which can be calculated from Equations 6.32.1

and 6.31.4. After specifying the recovery of the key component, the exit composi-

tion of the solvent stream is calculated from Equation 6.32.2. After calculating the

column diameter from Equations 6.32.7 and 6.32.8, use Equation 6.32.6 to calcu-

late the height of the extractor.

Although the size of the end sections of an extractor, where phase separation

occurs, could be calculated by a method similar to the one described in the section

on decanter sizing, a more approximate method will be used. Karr and Lo [62]

give the dimensions of the extractor used in their studies. The diameter of the end

section is 50 % greater than the column diameter, and its height is a little less than

the column diameter. For a pulsed-column extractor, Valle-Riestra '[53] used a

continuous-phase flux of 0.5 gal/min-ft 2 (3.40 m/min) and a height/diameter ratio

of 1.0 to size the end sections of an extractor. The cross-sectional area of the ex-

tractor, and hence, the diameter is calculated by dividing by the total volumetric

flow rate (the sum of the volumetric flow rates for both phases) by the total volu-

metric flow rate per unit of extractor cross-sectional area, obtained from Table

6.31. Then, add the diameter to the product of N e and HETS, as shown in Equation

6.32.6, to obtain the total column height.

The HETS for an extractor can be estimated by using the scaling rules de-

veloped by Karr and Lo [62] and experimental values of HETS summarized in

Table 6.31. First, determine if the extraction system is a low interfacial-tension

system or a high interfacial-tension system. Next, select a value of HETS from

Table 6.31 from the following systems:

low interfacial-tension - MIBK, acetic acid, water system

high interfacial-tension - o-xylene, acetic acid, water system

Then, scale this value of HETS for the extractor diameter using Equation 6.32.9. A

simpler procedure for obtaining HETS, however, is to use the correlation given by

Henley and Seader [31], shown in Figure 6.23. the correlation is acceptable for

both a low and high interfacial-tension system. The problem, however, is that in-

terfacial-tension data may not be available.

To complete sizing the Karr column requires sizing the electric motor. The

size of the electric motor to disperse one of the phases is small. Walas [51] states

that al.5hp(1.12 kW) motor is sufficient to agitate a Karr extractor 30 in (0.762

Copyright © 2003 by Taylor & Francis Group LLC