Page 39 - Chemical process engineering design and economics

P. 39

Processes and Process Engineering 25

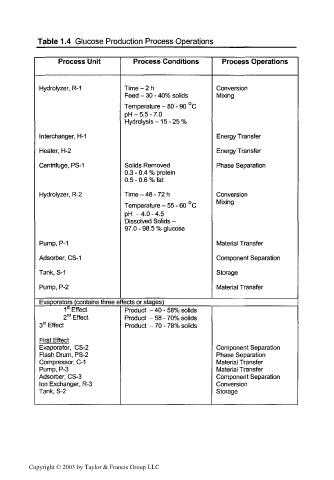

Table 1.4 Glucose Production Process Operations

Process Unit Process Conditions Process Operations

Hydrolyzer, R-1 Time -2 h Conversion

Feed - 30 - 40% solids Mixing

Temperature - 80 - 90 °C

pH - 5.5 - 7.0

Hydrolysis -15 -25%

Interchanger, H-1 Energy Transfer

Heater, H-2 Energy Transfer

Centrifuge, PS-1 Solids Removed Phase Separation

0.3 - 0.4 % protein

0.5 - 0.6 % fat

Hydrolyzer, R-2 Time -48- 72 h Conversion

Mixing

Temperature - 55 - 60 °C

pH -4.0-4.5

Dissolved Solids -

97.0 - 98.5 % glucose

Pump, P-1 Material Transfer

Adsorber, CS-1 Component Separation

Tank, S-1 Storage

Pump, P-2 Material Transfer

Evaporators (contains three effects or stages)

st

1 Effect Product - 40 - 58% solids

nd

2 Effect Product - 58 - 70% solids

rd

3 Effect Product - 70 - 78% solids

First Effect

Evaporator, CS-2 Component Separation

Flash Drum, PS-2 Phase Separation

Compressor, C-1 Material Transfer

Pump, P-3 Material Transfer

Adsorber, CS-3 Component Separation

Ion Exchanger, R-3 Conversion

Tank, S-2 Storage

Copyright © 2003 by Taylor & Francis Group LLC