Page 40 - Chemical process engineering design and economics

P. 40

26 Chapter 1

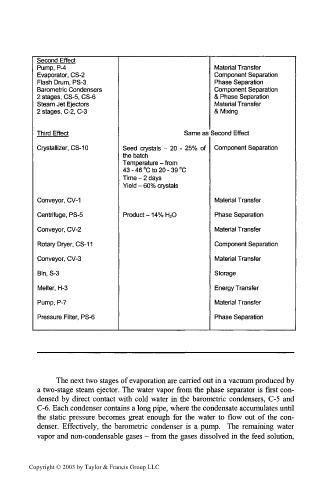

Second Effect

Pump, P-4 Material Transfer

Evaporator, CS-2 Component Separation

Flash Drum, PS-3 Phase Separation

Barometric Condensers Component Separation

2 stages, CS-5, CS-6 & Phase Separation

Steam Jet Ejectors Material Transfer

2 stages, C-2, C-3 & Mixing

Third Effect Same as Second Effect

Crystallizer, CS-10 Seed crystals - 20 - 25% of Component Separation

the batch

Temperature - from

43 - 46 °C to 20 - 39 °C

Time - 2 days

Yield - 60% crystals

Conveyor, CV-1 Material Transfer

Centrifuge, PS-5 Product-14% H 2O Phase Separation

Conveyor, CV-2 Material Transfer

Rotary Dryer, CS-11 Component Separation

Conveyor, CV-3 Material Transfer

Bin, S-3 Storage

Melter, H-3 Energy Transfer

Pump, P-7 Material Transfer

Pressure Filter, PS-6 Phase Separation

The next two stages of evaporation are carried out in a vacuum produced by

a two-stage steam ejector. The water vapor from the phase separator is first con-

densed by direct contact with cold water in the barometric condensers, C-5 and

C-6. Each condenser contains a long pipe, where the condensate accumulates until

the static pressure becomes great enough for the water to flow out of the con-

denser. Effectively, the barometric condenser is a pump. The remaining water

vapor and non-condensable gases - from the gases dissolved in the feed solution,

Copyright © 2003 by Taylor & Francis Group LLC