Page 413 - Chemical process engineering design and economics

P. 413

Reactor Design 393

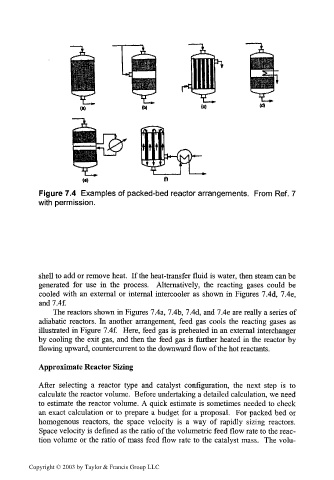

Figure 7A Examples of packed-bed reactor arrangements. From Ref. 7

with permission.

shell to add or remove heat. If the heat-transfer fluid is water, then steam can be

generated for use in the process. Alternatively, the reacting gases could be

cooled with an external or internal intercooler as shown in Figures 7 Ad, 7Ae,

and lAf.

The reactors shown in Figures 7Aa, 7Ab, 7.Ad, and 7Ae are really a series of

adiabatic reactors. In another arrangement, feed gas cools the reacting gases as

illustrated in Figure 7Af. Here, feed gas is preheated in an external interchanger

by cooling the exit gas, and then the feed gas is further heated in the reactor by

flowing upward, countercurrent to the downward flow of the hot reactants.

Approximate Reactor Sizing

After selecting a reactor type and catalyst configuration, the next step is to

calculate the reactor volume. Before undertaking a detailed calculation, we need

to estimate the reactor volume. A quick estimate is sometimes needed to check

an exact calculation or to prepare a budget for a proposal. For packed bed or

homogenous reactors, the space velocity is a way of rapidly sizing reactors.

Space velocity is defined as the ratio of the volumetric feed flow rate to the reac-

tion volume or the ratio of mass feed flow rate to the catalyst mass. The volu-

Copyright © 2003 by Taylor & Francis Group LLC