Page 414 - Chemical process engineering design and economics

P. 414

394 Chapter 7

volume or the ratio of mass feed flow rate to the catalyst mass. The volumetric

feed-gas flow rate is calculated at a standard temperature and pressure. Thus,

the space velocity is defined by:

GHSV = hourly volumetric feed-gas flow rate/reaction volume

LHSV = hourly volumetric liquid-feed flow rate/reaction volume

WHSV = hourly mass feed flow rate/catalyst mass

The units of space velocity are the reciprocal of time. Usually, the hourly

volumetric feed-gas flow rate is calculated at 60 °F (15.6 °C) and 1.0 arm (1.01

bar). The volumetric liquid-feed flow rate is calculated at 60 °F (15.6 °C). Space

velocity depends on the design of the reactor, reactor inlet conditions, catalyst

type and diameter, and fractional conversion. Walas [7] has tabulated space

velocities for 102 reactions. For example, for the homogeneous conversion of

benzene to toluene in the gas phase, the hourly-volumetric space velocity is 815

1

h" . This means that 815 reactor volumes of benzene at standard conditions will

be converted in one hour. Although space velocity has limited usefulness, it

allows estimating the reaction volume rapidly at specified conditions. Other

conditions require additional space velocities. A kinetic model is more useful

than space velocities, allowing the calculation of the reaction volume' at different

operating conditions, but a model requires more time to develop, and frequently

time is not available.

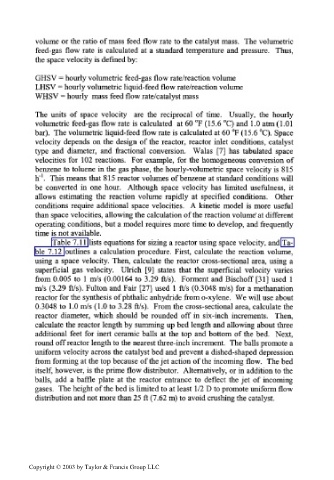

Table 7.11 lists equations for sizing a reactor using space velocity, and Ta-

ble 7.12 outlines a calculation procedure. First, calculate the reaction volume,

using a space velocity. Then, calculate the reactor cross-sectional area, using a

superficial gas velocity. Ulrich [9] states that the superficial velocity varies

from 0.005 to 1 m/s (0.00164 to 3.29 ft/s). Forment and Bischoff [31] used 1

m/s (3.29 ft/s). Fulton and Fair [27] used 1 ft/s (0.3048 m/s) for a methanation

reactor for the synthesis of phthalic anhydride from o-xylene. We will use about

0.3048 to 1.0 m/s (1.0 to 3.28 ft/s). From the cross-sectional area, calculate the

reactor diameter, which should be rounded off in six-inch increments. Then,

calculate the reactor length by summing up bed length and allowing about three

additional feet for inert ceramic balls at the top and bottom of the bed. Next,

round off reactor length to the nearest three-inch increment. The balls promote a

uniform velocity across the catalyst bed and prevent a dished-shaped depression

from forming at the top because of the jet action of the incoming flow. The bed

itself, however, is the prime flow distributor. Alternatively, or in addition to the

balls, add a baffle plate at the reactor entrance to deflect the jet of incoming

gases. The height of the bed is limited to at least 1/2 D to promote uniform flow

distribution and not more than 25 ft (7.62 m) to avoid crushing the catalyst.

Copyright © 2003 by Taylor & Francis Group LLC