Page 469 - Chemical process engineering design and economics

P. 469

448 Chapter 8

Cavitation

If the pressure in a flowing liquid falls below its vapor pressure, the liquid will

vaporize. If vapor bubbles form on the suction side of the pump, the bubbles will

move with the stream and will subsequently collapse in a region of high pressure.

This phenomenon is called cavitation. Dissolved gases in the fluid, such as air in

water, could also form bubbles. The collapsing vapor or gas bubbles subject the

pump surfaces to tremendous shock. The energy involved in the shock is explo-

sive enough to flake off small bits of metal and in time the pump will become pit-

ted. Cavitation also results in a loss of energy. Immediate clues of cavitation are

reduced flow rate, loss of head, pumping in spurts, and excessive noise and vibra-

tion.

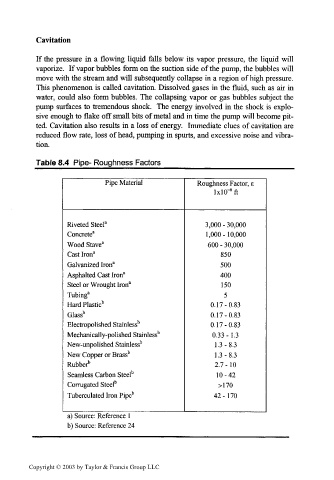

Table 8.4 Pipe- Roughness Factors

Pipe Material Roughness Factor, E

IxlO^ft

Riveted Steel 3 3,000 - 30,000

Concrete 3 1,000-10,000

Wood Stave" 600 - 30,000

Cast Iron" 850

Galvanized Iron 3 500

Asphalted Cast Iron" 400

Steel or Wrought Iron" 150

Tubing" 5

Hard Plastic b 0.17-0.83

Glass b 0.17-0.83

Electropolished Stainless b 0.17-0.83

Mechanically-polished Stainless b 0.33-1.3

New-unpolished Stainless b 1.3-8.3

New Copper or Brass b 1.3-8.3

Rubber b 2.7-10

Seamless Carbon Steel b 10-42

Corrugated Steel b >170

Tuberculated Iron Pipe b 42-170

a) Source: Reference 1

b) Source: Reference 24

Copyright © 2003 by Taylor & Francis Group LLC