Page 12 - Chiral Separation Techniques

P. 12

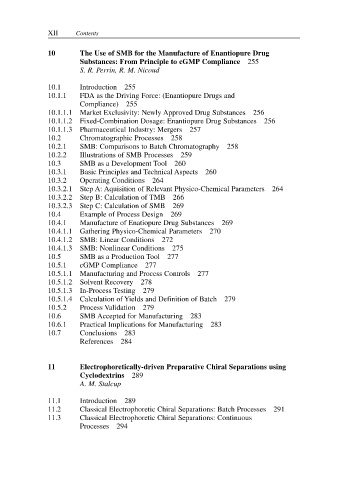

XII Contents

10 The Use of SMB for the Manufacture of Enantiopure Drug

Substances: From Principle to cGMP Compliance 255

S. R. Perrin, R. M. Nicoud

10.1 Introduction 255

10.1.1 FDA as the Driving Force: (Enantiopure Drugs and

Compliance) 255

10.1.1.1 Market Exclusivity: Newly Approved Drug Substances 256

10.1.1.2 Fixed-Combination Dosage: Enantiopure Drug Substances 256

10.1.1.3 Pharmaceutical Industry: Mergers 257

10.2 Chromatographic Processes 258

10.2.1 SMB: Comparisons to Batch Chromatography 258

10.2.2 Illustrations of SMB Processes 259

10.3 SMB as a Development Tool 260

10.3.1 Basic Principles and Technical Aspects 260

10.3.2 Operating Conditions 264

10.3.2.1 Step A: Aquisition of Relevant Physico-Chemical Parameters 264

10.3.2.2 Step B: Calculation of TMB 266

10.3.2.3 Step C: Calculation of SMB 269

10.4 Example of Process Design 269

10.4.1 Manufacture of Enatiopure Drug Substances 269

10.4.1.1 Gathering Physico-Chemical Parameters 270

10.4.1.2 SMB: Linear Conditions 272

10.4.1.3 SMB: Nonlinear Conditions 275

10.5 SMB as a Production Tool 277

10.5.1 cGMP Compliance 277

10.5.1.1 Manufacturing and Process Controls 277

10.5.1.2 Solvent Recovery 278

10.5.1.3 In-Process Testing 279

10.5.1.4 Calculation of Yields and Definition of Batch 279

10.5.2 Process Validation 279

10.6 SMB Accepted for Manufacturing 283

10.6.1 Practical Implications for Manufacturing 283

10.7 Conclusions 283

References 284

11 Electrophoretically-driven Preparative Chiral Separations using

Cyclodextrins 289

A. M. Stalcup

11.1 Introduction 289

11.2 Classical Electrophoretic Chiral Separations: Batch Processes 291

11.3 Classical Electrophoretic Chiral Separations: Continuous

Processes 294