Page 243 - Chiral Separation Techniques

P. 243

9.2 The SMB Concept 221

9.2 The SMB Concept

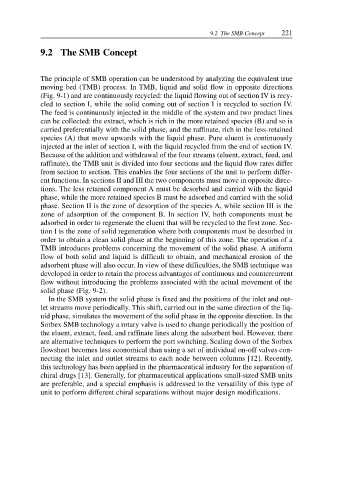

The principle of SMB operation can be understood by analyzing the equivalent true

moving bed (TMB) process. In TMB, liquid and solid flow in opposite directions

(Fig. 9-1) and are continuously recycled: the liquid flowing out of section IV is recy-

cled to section I, while the solid coming out of section I is recycled to section IV.

The feed is continuously injected in the middle of the system and two product lines

can be collected: the extract, which is rich in the more retained species (B) and so is

carried preferentially with the solid phase, and the raffinate, rich in the less-retained

species (A) that move upwards with the liquid phase. Pure eluent is continuously

injected at the inlet of section I, with the liquid recycled from the end of section IV.

Because of the addition and withdrawal of the four streams (eluent, extract, feed, and

raffinate), the TMB unit is divided into four sections and the liquid flow rates differ

from section to section. This enables the four sections of the unit to perform differ-

ent functions. In sections II and III the two components must move in opposite direc-

tions. The less retained component A must be desorbed and carried with the liquid

phase, while the more retained species B must be adsorbed and carried with the solid

phase. Section II is the zone of desorption of the species A, while section III is the

zone of adsorption of the component B. In section IV, both components must be

adsorbed in order to regenerate the eluent that will be recycled to the first zone. Sec-

tion I is the zone of solid regeneration where both components must be desorbed in

order to obtain a clean solid phase at the beginning of this zone. The operation of a

TMB introduces problems concerning the movement of the solid phase. A uniform

flow of both solid and liquid is difficult to obtain, and mechanical erosion of the

adsorbent phase will also occur. In view of these difficulties, the SMB technique was

developed in order to retain the process advantages of continuous and countercurrent

flow without introducing the problems associated with the actual movement of the

solid phase (Fig. 9-2).

In the SMB system the solid phase is fixed and the positions of the inlet and out-

let streams move periodically. This shift, carried out in the same direction of the liq-

uid phase, simulates the movement of the solid phase in the opposite direction. In the

Sorbex SMB technology a rotary valve is used to change periodically the position of

the eluent, extract, feed, and raffinate lines along the adsorbent bed. However, there

are alternative techniques to perform the port switching. Scaling down of the Sorbex

flowsheet becomes less economical than using a set of individual on-off valves con-

necting the inlet and outlet streams to each node between columns [12]. Recently,

this technology has been applied in the pharmaceutical industry for the separation of

chiral drugs [13]. Generally, for pharmaceutical applications small-sized SMB units

are preferable, and a special emphasis is addressed to the versatility of this type of

unit to perform different chiral separations without major design modifications.