Page 302 - Civil Engineering Formulas

P. 302

236 CHAPTER NINE

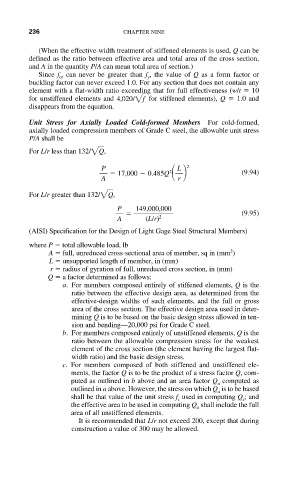

(When the effective-width treatment of stiffened elements is used, Q can be

defined as the ratio between effective area and total area of the cross section,

and A in the quantity P/A can mean total area of section.)

Since f can never be greater than f , the value of Q as a form factor or

cr

y

buckling factor can never exceed 1.0. For any section that does not contain any

element with a flat-width ratio exceeding that for full effectiveness (w/t 10

for unstiffened elements and 4,020/ 2 f for stiffened elements), Q 1.0 and

disappears from the equation.

Unit Stress for Axially Loaded Cold-formed Members For cold-formed,

axially loaded compression members of Grade C steel, the allowable unit stress

P/A shall be

For L/r less than 132/ 2 Q,

L

P 2

17,000 0.485Q 2 (9.94)

A r

For L/r greater than 132/ 2 Q,

P 149,000,000

(9.95)

A (L/r) 2

(AISI) Specification for the Design of Light Gage Steel Structural Members)

where P total allowable load, lb

2

A full, unreduced cross-sectional area of member, sq in (mm )

L unsupported length of member, in (mm)

r radius of gyration of full, unreduced cross section, in (mm)

Q a factor determined as follows:

a. For members composed entirely of stiffened elements, Q is the

ratio between the effective design area, as determined from the

effective-design widths of such elements, and the full or gross

area of the cross section. The effective design area used in deter-

mining Q is to be based on the basic design stress allowed in ten-

sion and bending—20,000 psi for Grade C steel.

b. For members composed entirely of unstiffened elements, Q is the

ratio between the allowable compression stress for the weakest

element of the cross section (the element having the largest flat-

width ratio) and the basic design stress.

c. For members composed of both stiffened and unstiffened ele-

ments, the factor Q is to be the product of a stress factor Q, com-

puted as outlined in b above and an area factor Q computed as

a

outlined in a above. However, the stress on which Q is to be based

a

shall be that value of the unit stress f used in computing Q ; and

c s

the effective area to be used in computing Q shall include the full

a

area of all unstiffened elements.

It is recommended that L/r not exceed 200, except that during

construction a value of 300 may be allowed.